E Waste Recycling Plant

- Product Introduction:

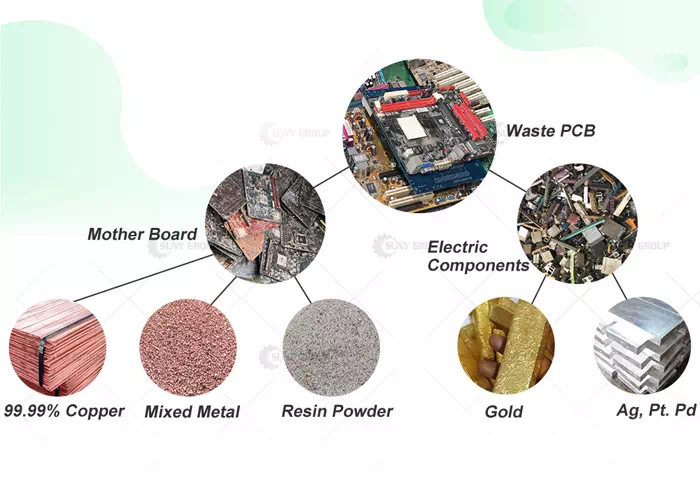

Suny Group is specialized in providing Complete E Waste Recycling Plant. Turning E-waste into treasure through different equipment not only solves the problem of environmental pollution, but also realizes resource recycling and reuse, and can also obtain high economic benefits.

Video Description:

Product Description:

SunyGroup is specialized in providing Complete E Waste Recycling Plant. Turning E-waste into treasure through different equipment not only solves the problem of environmental pollution, but also realizes resource recycling and reuse, and can also obtain high economic benefits.

Part1:PCB Dismantling Machine

PCB Components Dismantling Machine is used to remove the electronic components on different PCB boards, The drumar made of 6mm thickness #45 steel and its own special technology, which have the characteristics of high temperature resistance, abrasion resistance, safety and reliable, stable performance, high precision, durability.

Technical Parameters:

Model Power(kw) Weight (kg) Capacity(kg/h) Dimension(m) ZCJ-200 0.75+1.1+3 350+100 200 1.67*0.97*1.4 ZCJ-300 0.75+2.2+3 500+200 300 1.85*1.2*1.52 ZCJ-500 0.75+3+3 800+300 500 2.1*1.27*1.74 Part2:PCB Crushing Seprating Production Line

PCB Crushing Seprating Production Line is used to recycle all kinds of Printed Circuit boards, such as the computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the separation of leftover material of the mixed metal and nonmetal materials.

Because of the high value of the metals, fiber and resin, there is no doubt that this plant not only help to change waste into treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

Technical Parameters:

Type Output(kg/h) Total power(KW) Occupied area(m2) ZY-BRB300 300-400 55 90 ZY-BRB500 500-600 65 120 ZY-BRB800 600--800 75 150 ZY-BRB1000 800-1000 120 200 Part3:Gold Deplating System

Green Recycling Gold Refining Equipment E Waste Recycle Machine is aimed at the gold stripping treatment of gold-plated materials in discarded electronic products.

Technical Parameters:

Option Specification Another Name Gold Deplating Machine Capacity Depends on the size of the reaction tank Operators 1-3 Workers Purity 99% Part4:Precious Metal Refine Plant

Precious Metal Refining Plant is used for recovery and refining precious metals such as gold, silver, palladium and platinum from electronic waste containing precious metal chip components and anode mud.

The raw materials are various chips containing precious metals and anode mud, the chips mainly include MLCC, North-South Bridge,Memory Chip, Chip Capacitor, etc.

For some components dismanlted from circuit boards, some of them surface plated gold, such as CPU, it will be first to do surface stripping process, to remove and extract the surface gold firstly, the following is the CPU before stripped and after stripped comparison.

Technical Parameters:

Model Capacity Power Recycle rate Purity GJ-100 100kg/day 20kw ≥99% ≥99% GJ-300 300kg/day 30kw ≥99% ≥99% Part5:Copper Electrolysis Equipment

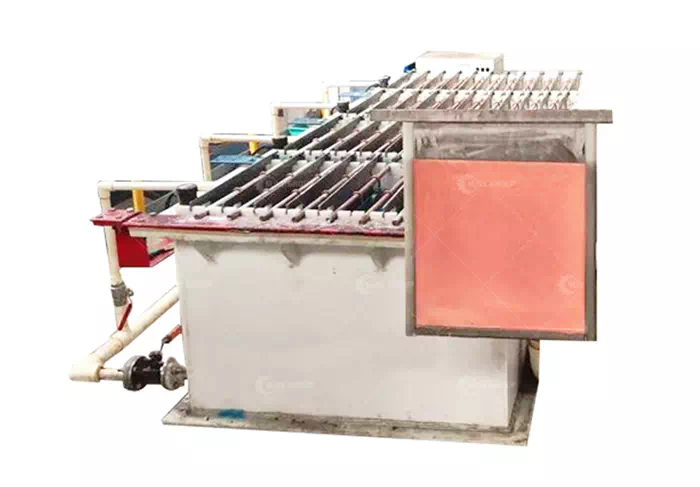

Copper is a good conductor of electricity, and is used extensively to make electrical wiring and components. The purification of copper is a form of recycling. Copper is purified further using electrolysis and we call it Copper Electrorefining (electrolytic refining).

In industry this is carried out on a massive scale. The electrolytic copper production is processed in the huge copper electrolytic tank fulfilled with copper electrolytic solution. Even the best chemical method cannot remove all the impurities from the copper, but with electrolytic refining it is possible to produce 99.99% pure copper (whatever method is used to manufacture copper from its ore, its final purification is by electrolysis).

Copper Electrolysis Refining TanksAnode plates are hung by their "handles" in electrolytic copper refining tank. Pure copper cathode sheets suspended on solid copper bars are inserted into the same tank, one sheet between each anode. When an electric current is passed from the anodes through the electrolyte to the cathodes, copper from the anodes moves into the solution and is plated onto the starter sheet. Impurities from the anodes settle to the bottom of the tank.

Technical Parameters:

Model Mixed metal powder Energy consumption(KWH) Electrolytic cycle(Anode/Cathode) Copper capacity Copper purity DJ-500 500kg/d 280 15days/48h 370 99.9% DJ-1000 1000kg/d 570 15days/48h 750 99.9% DJ-2000 2000kg/d 1130 15days/48h 1500 99.9% DJ-5000 5000kg/d 2850 15days/48h 3750 99.9% Customer Sites

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231