Double Shredder Machine

- Product Introduction:

Double Shaft Shredding Machine is suitable for all kinds of hollow containers: plastic beverage cans, plastic buckets, iron drums, packing boxes, packing drums; automobile housing, aluminum alloy, scrap cast aluminum parts, engine housing, lead and steel plates with thickness below 5mm, etc.

Video Description:

PRODUCT DESCRIPTION:

Double Shaft Shredding Machine is suitable for all kinds of hollow containers: plastic beverage cans, plastic buckets, iron drums, packing boxes, packing drums; automobile housing, aluminum alloy, scrap cast aluminum parts, engine housing, lead and steel plates with thickness below 5mm, etc.

SUITABLE RAW MATERIALS:

1. All kinds of hollow containers: plastic beverage cans, plastic buckets, iron drums, packing boxes, packing drums.

2. Used household appliances: TV, washing machine, refrigerator shell.

3. Pipe material: large pipe, pipe fitting and PE pipe.

4. Used templates: wooden pallets, plastic pallets and forklifts.

5. Used tires: car tires, truck tires.

6. Scrap metal: automobile housing, aluminum alloy, scrap cast aluminum parts, engine housing, lead and steel plates with thickness below 5mm.

7. Cooking garbage, living garbage, RDF derivative, medical waste, biological orange pole, garden garbage.

8. Glue head material, paper mill rope.

MAIN STRUCTURES:

1. Shaft, moving blades, fixed blades, reducer, motors, feeding hopper, discharge port, electric control cabinet, control panel, screen, roller, knives holder, ect.

2. After shreddering, the dimension of most large plastic or other material will reduce 30%, some material dimenison after shreddering can up to 50%.

(We have arranged many videos. Please contact us freely if you need.)

1. We design the blades with different hooks, and the thickness of blades for different materials are different, the range is 10mm-80mm. Blade quality have 9CrSi, Cr12MoV, SKD-II, D2 etc.

2. The main body of the shredder is welded with high quality steel plate to eliminate stress treatment/integral machining to ensure the stability of the equipment under heavy load for a long time.

3. Knife shaft is is made of special special alloy tool steel forging blank, precision machining, multiple heat treatment, and reasonably provided powerful power for cutting, increase service life.

4. Our double shaft shredder adopts button control, easy to operate, set up, stop, reverse, overload protection and other functions.

SHREDDING PROCESS:

WORKING PRINCIPLE:

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customers' material;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

FEATURE:

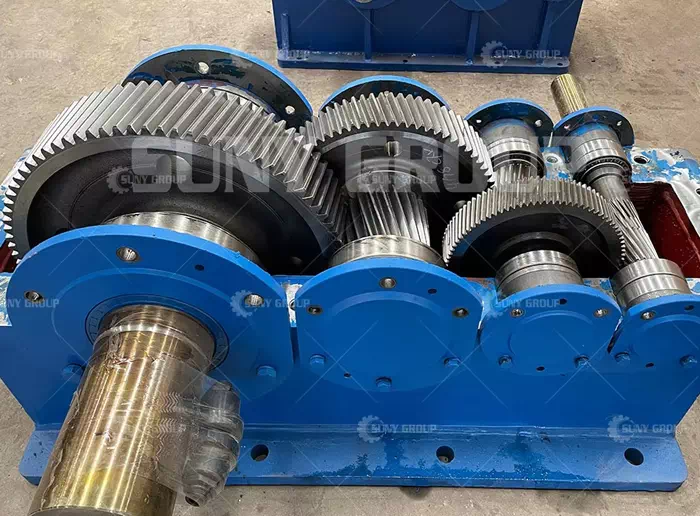

1.The three-stage four-axis transmission of the reducer, the gears are made of high-strength low-carbon alloy steel through carburizing and quenching, the tooth surface has high hardness, and the gears adopt theCNC integrated gear grinding process.

2.Shred chamber plate is very thick, can resist high torque.

3.Controlled by PLC control system; the blade can reverse automatically to protect the machine when overload.

4.We design single or multi-hooks of blades with different thickness for different materials.

5.The bearing seat adopts the split type, easy to maintain and replace the blade.

6.The feeding hopper can be customized according to the customer's site to facilitate the input of materials of different sizes.

TECHNICAL PARAMETERS:

Model ZY-D600 ZY-D800 ZY-D1000 ZY-D1200 Motor power (kw) 7.5+7.5 15+15 18.5+18.5 30+30 Capacity (kg/h) 500-600 700-800 800-1000 1000-1200 Cutter (pcs) 22 30 30 36 Shredding room size (mm) 600x430 800x430 1000x500 1000x580 Weight (kg) 2300 3300 5000 6800

NOTE:

1. The above shredder is our standard configuration. For different raw materials to be shredded, the configuration might be different. Please feel free to contact us for detailed information or special request;

2. We have welding, removable and integral blade holders for our single shaft shredder. You can communicate with our sales representative to confirm the suitable blade holder.

CLIENT FEEDBACK:

We sell not only equipment, but also reliable after-sales service, we provide customers with wiring diagrams, installation diagrams, foundation diagrams for installation and all-day online services.

FAQ:

Q: Why Choose Us?

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery:

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: Yes, you can. It depends on the difference of blades teeth and quantity, which can be customized.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

RELATED MACHINERY:

Mini Double Shaft Shredder

-

Product Introduction:

Mini Double Shaft Shredder is a small and efficient shredding machine for plastic, metal, cardboard and other materials, powerful and cost-effective for small recycling scenarios.

Single Shaft Shredder Machine

-

Product Introduction:

Single Shaft Shredder Machine adopts European advanced technology, is mainly applied in the crushing...

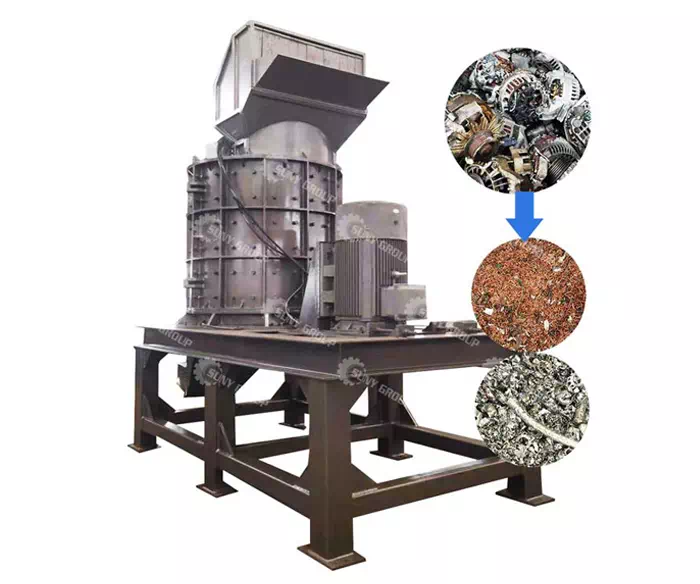

Alternators Staters Hammer Crusher

-

Product Introduction:

The Alternators Starters Hammer Crusher is a heavy-duty crushing plant designed to pulverize a wide range of metal materials for subsequent sorting and recycling.

-

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231