Solar Panel Recycling Plant

- Product Introduction:

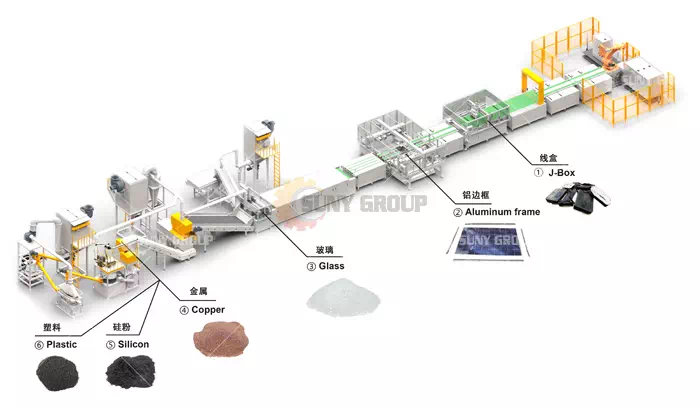

With solar PV panel recycling machines, valuable materials such as copper, silver, silicon, plastics, and glass can be recovered from their components such as aluminum frames, toughened glass, EVA encapsulation materials, solar cells, back sheets, and junction boxes and reused in the production process.

Video Description:

PRODUCT DESCRIPTION:

Solar PV recycling (photovoltaic) is an up and coming waste stream generated in both consumer and commercial fields of use. While demand may not be terribly high at the moment, there are many early-era solar power systems or solar PV systems that will soon be reaching their end of life cycle. SUNY GROUP stands ready to deliver industry leading end of life management solutions for commercial and consumer solar energy systems.

The rest of the components in a solar panel consist of good quality glass, aluminium frames, polymers,silicon, copper and silver paste (used for the printed conductors on each cell), all of which (≥95%), can be successfully recycled.

RECYCLING TECHNOLOGY

Our advanced Solar Panel Recycling Machine ensures continuous, high-efficiency material recovery through the following steps:

1.Initial Dismantling: The process begins with specialized machines. The J-boxre- moving machine removes the junction box from the solar panels. Subsequently, the Aluminum frame removing machine is used to accurately separate the aluminum frame from the panel edges.

2.Glass Separation: The panel proceeds to the Glass removing machine. This unit is crucial for mechanical separation, designed to remove the majority of the glass from the panel surface.

3.Shredding and Crushing: The pre-treated photovoltaic panels (with aluminum frame and glass removed) first enter the twin shaft shredder to be torn into strips. Following this, the material moves to the crusher, which reduces the material into small pieces of 1-2 cm.

4.Fine Grinding and Air Separation: These small pieces are fed via negative pressure into the Fine grinder. Our fine grinder is configured with a return material system to re-process any particles that do not meet the size requirements. Qualified material then enters the air separator, which screens out the metal powder from one side, separating it from the plastic and remaining small amount of metal on the other side.

5.Final Electrostatic Sorting: The mixture of plastic and trace metal is then directed to the electrostatic separator. This highly efficient step ensures that pure plastic and high-purity metal are precisely sorted and recovered, finalizing the high-grade output.

SYSTEM STRUCTURE

The complete Solar Panel Recycling Plant is organized into four main functional sections:

PART 1: J-boxre moving machine: Suitable for solar panels with one or more J-boxes.

PART 2: Aluminum frame removing machine: Removing the aluminum frame at the edge of the solar panel.

PART 3: Glass removing machine: To Remove Glass from the Surface.

PART 4: Crushing and sorting machines: The treated solar panels then pass through the crushing and sorting equipment to obtain high-purity silicon powder, metal, plastic.

CORE ADVANTAGES

Our Solar Panel Recycling Machine offers significant advantages:

1.Fully Automated and High Efficiency: The process design is fully automated, significantly reducing labor costs and accelerating the processing speed to enhance overall production efficiency.

2.Eco-Friendly Physical Process: The entire system relies on purely physical means. Crucially, the equipment is equipped with dust removal equipment, ensuring no dust and pollution occur during the working process.

3.High-Purity Final Products: The integrated crushing and sorting processes yield high-quality output materials, including high-purity metal powder and plastic.

TECHNICAL PARAMETER

Model Power(KW) Dimension(mm) Capacity PVR-60 300 55000*8671*5000 50-60PCS/H PVR-1500 390 57000*8000*6000 1000-1500KG/H PVR-F60 240 108000*11000*5500 50-60PCS/H Note:

* Operating voltage: Standard voltage is 380 ± 10 V; custom voltages such as 415 V and 440 V are also available.

* Custom Solutions: The parameters and configurations above are for reference only. We offer customized Solar Panel Recycling Solutions and machines. Please contact us anytime to discuss your specific requirements.

- {dede:field.xntd/}

- {dede:field.gylc/}

- {dede:field.jgzc/}

- {dede:field.gzyl/}

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231