Al-Cu Radiator Separating Recycling Machine

Aluminum (Al) and copper (Cu) heat sinks are widely used in various electrical appliances and vehicles due to their excellent heat dissipation performance. However, at the end of their life cycle, they can become a lot of waste. Reasonable and effective recovery of copper and aluminum from aluminum-copper radiators is a common solution at present, usually requiring the use of copper-aluminum separation machines.

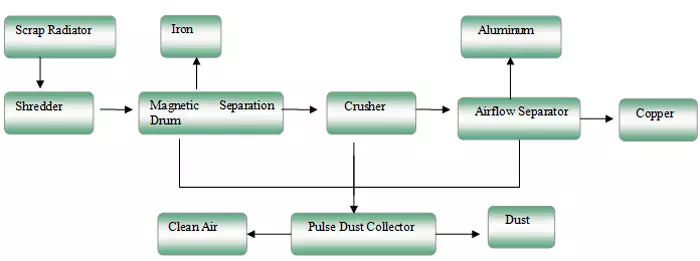

The aluminum copper radiator recycling process involves multiple steps, each employing specific equipment to ensure efficiency and safety.

1. Preprocessing

Al-Cu radiator recycling process

Radiators require pretreatment prior to the recycling process, which often involves manual disassembly to remove attached plastic and steel components. Then use a shredder to crush the radiator into small pieces. This machine can effectively reduce the size of the heat sink, making it suitable for the next stage of the process.

2. Separation

The broken radiator material then undergoes a separation process. The modern air-conditioning radiator crushing and separating machine is a comprehensive equipment integrating crushing and separation functions. It uses a combination of crushing, winnowing and magnetic separation to separate copper and aluminum from other materials.

The separator uses a high-speed fan to create an airflow that blows the lighter aluminum particles into a different compartment, while the heavier copper particles fall into another section. An integrated magnetic separator then removes any remaining ferrous material, ensuring a clean output of separated aluminum and copper.

3. Refinement

The separated metal may still contain some degree of impurities. Electrostatic separators can further refine the material. The machine uses electrical charges to attract or repel charged particles, resulting in a high degree of separation of remaining impurities from copper and aluminum.

Recycled Copper and Aluminum

The aluminum copper radiator separation recycling machine not only provides an effective way to recover valuable materials, but also has the following advantages:

1. Resource saving: By recycling aluminum and copper from waste radiators, we reduce the need for new raw materials, thereby reducing the amount of mining and saving resources.

2. Efficient and stable: Through the copper and aluminum radiator recycling production line, a large number of copper and aluminum radiators can be crushed, sorted and recycled in batches. It is not only stable and efficient, but also equipped with dust removal equipment, which will not pollute the environment.

3. Economic value: Recycled aluminum and copper can be sold back into the market, generating revenue and making the recycling process economically viable.

4. Wide range of use: can handle various radiators from various sources, making it highly versatile.

Customer copper aluminum radiator separator site

The Aluminum Copper Radiator Separation and Recycling Machine developed by SUNY GROUP represents a crucial step towards a more sustainable and circular economy. The ability to recover valuable materials from discarded radiators offers significant environmental, economic and resource conservation benefits. As we continue to work toward more sustainable practices, these technologies will play an increasingly important role in our efforts. If you have any needs, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231