Aluminum and Plastic (PE) Separation to Enhance Aluminum Recovery

Aluminum is an extremely valuable and versatile material and an element that can be efficiently recycled. There are a lot of aluminum-plastic waste in real life, such as waste medical boards, aluminum-plastic boards, toothpaste skins, etc. In order to obtain more pure aluminum for recycling, it is crucial to effectively separate it from plastics (especially polyethylene or PE) important. This paper discusses the equipment and advantages of aluminum-plastic separation technology in improving the purity of recycled aluminum.

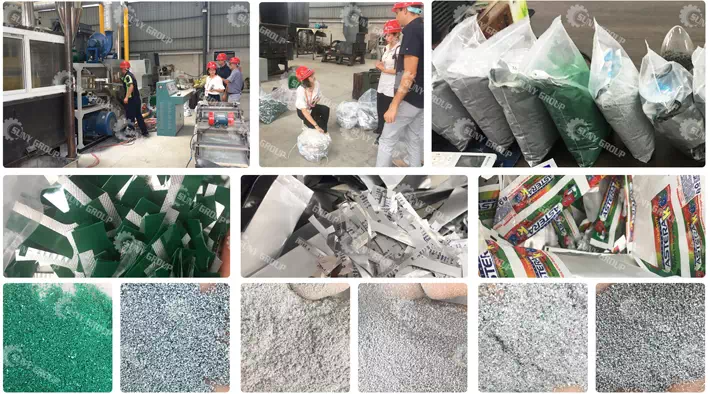

Crushing and milling machine: A large amount of aluminum-plastic waste collected needs to be crushed and pulverized first, and crushed into fine particle powder to facilitate the next step of sorting.

Bulgaria customer take three kinds of materials testing our aluminum plastic recylcing machine

Vortex separator:

Vortex separators are designed to separate non-ferrous metals, including aluminum, from mixed waste streams. By inducing magnetic fields to create eddy currents in conductive materials, these separators repel aluminum particles, keeping them out of the waste stream. Eddy current separators efficiently separate aluminum from plastic, ensuring a cleaner aluminum component.

Electrostatic separator:

The electrostatic separator is a device that uses the principle of electrostatic force to separate different components in the mixture according to the electrical difference of the material. It can be used to treat mixed waste, such as a mixture of plastic and aluminum. By taking advantage of the electrical difference between plastic and metal, the two can be separated for efficient recycling and resource utilization.

Advantages of aluminum-plastic separation:

Aluminum plastic separator recycling equipment

Improve Aluminum Purity:

By employing effective separation techniques, purer aluminum can be obtained for recycling. Removing plastic contaminants ensures higher quality aluminum, which can be used in various industries including automotive, construction and packaging.

Improve recycling efficiency:

Aluminum and plastic separation technology increases the overall efficiency of the recycling process. By separating aluminum from plastic, recycling facilities can simplify the sorting and processing stages, reducing time and energy consumption.

Minimize environmental impact:

Separating aluminum from plastic helps reduce environmental impact. By recycling aluminum in a purer form, the need for primary aluminum extraction can be reduced, saving energy and reducing greenhouse gas emissions.

Aluminum and plastic separation technology developed by SUNY GROUP plays a vital role in achieving purer aluminum recycling. The above-mentioned equipment, shredder, pulverizer, and electrostatic separation machine are the key equipment in this process. By effectively separating aluminum from plastic, the recycling industry can increase the purity of aluminum, improve recycling efficiency, and minimize environmental impact, while also reaping certain economic benefits from it. If you are interested in the separation of aluminum and plastic, or have a need, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231