Aluminum-plastic recycling machine for blister packs

There are many aluminum-plastic products in our daily life, such as milk carton, capsule board, aluminum-plastic wrapping paper, toothpaste skin, etc. Because these aluminum-plastic scraps contain a large amount of aluminum, so they have a high recycling value, especially aluminum-plastic blister materials, because the application range is more extensive and the aluminum content is high, so it has a better recycling economic value.

The aluminum-plastic separator developed and manufactured by SUNY GROUP can effectively separate and reuse various aluminum-plastic materials, especially aluminum-plastic blister waste.

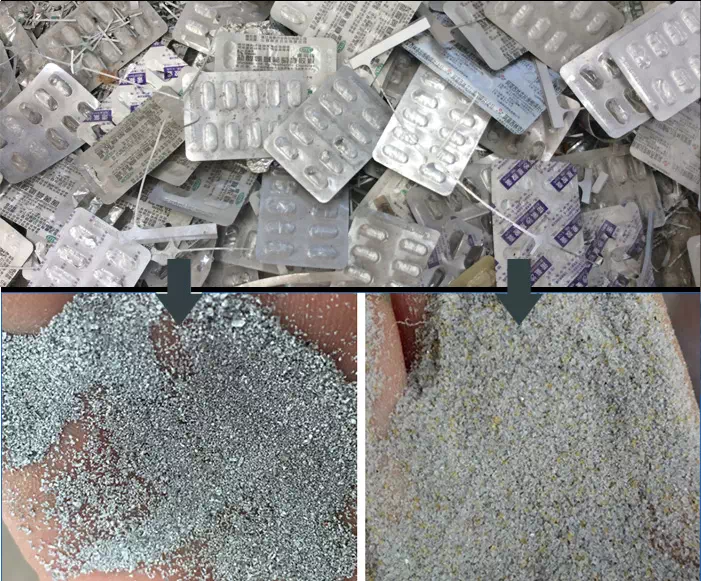

After aluminum plastic blister separationt

The aluminum-plastic separating and recycling equipment separates metal and non-metal from aluminum-plastic blister scrap by crushing and electrostatic sorting. First, a large amount of material is sent into the crusher for secondary crushing and three-stage grinding to dissociate, then the material that meets the particle size requirements is separated by rotary screening, and then the plastic and aluminum are separated by a double-roller shaft electrostatic sorter. All the process is physical separation, no heating burning water and chemical, so it is very environmental friendly and no pollution. Its process is low cost, high efficiency and separation rate can reach 99.8%. And the equipment is fully automatic production line, saving labor, only one or two are enough to operate the machine. The production line is widely used, easy to install, with various assembly methods, which can be adapted to different places.

Because there is PVC material in the aluminum-plastic composite material, plus the unique two to four cavity structure, the inner and outer layers of aluminum alloy lamination, with insulation, heating separation method is the use of this feature to deal with, but at the same time there is smoke and odor and other harmful substances generated, not ideal; and some use of potion separation is not environmentally friendly. The special crusher to crush aluminum and plastic materials to 1.5mm particle size below, due to the difference between the softening value of the two materials, such mixed particles are very suitable for high pressure electric separator, coupled with the dust removal device, no dust and high separation purity. The big advantage of this production line is that the separated aluminum and plastic granules can directly enter the market and be sold, which cannot be achieved by other methods.

Environmentally friendly aluminum-plastic separator, separation equipment, separator features.

1、High automation program, simple operation, stable performance

2, low power consumption, low noise, small footprint, no dust pollution

3、Electrical separation efficiency of 99%, the finished product can be directly marketed.

The above is the introduction of aluminum and plastic blister recycling equipment, if you have the need or interest in this area, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231