Aluminum-plastic waste separation and recycling process equipment

The separation and recovery process equipment of aluminum-plastic waste is an effective and sustainable solution to the recycling and reuse of aluminum-plastic waste. The application range and advantages of the aluminum-plastic waste separation and recycling process and its equipment are as follows:

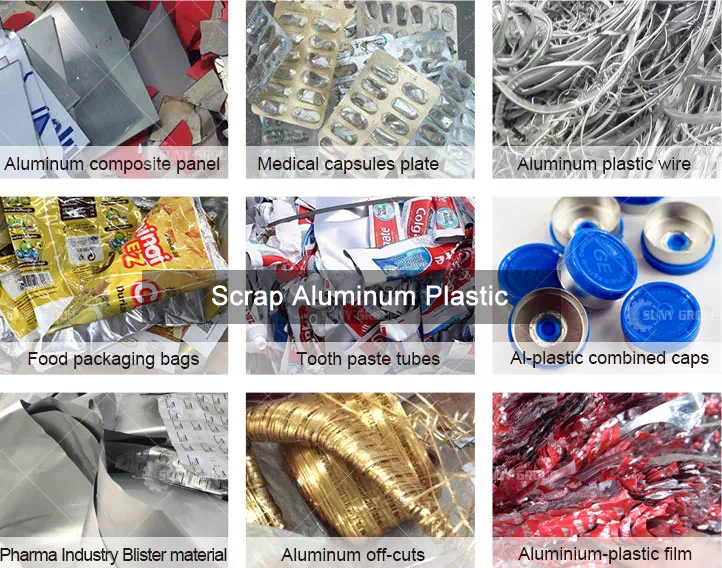

Scrap-Aluminum-Plastic

1. Process overview: Aluminum-plastic waste separation and recycling process is a method of separating aluminum and plastic through mechanical force and physical process. The process is mainly divided into the following steps:

Pretreatment: First, the collected aluminum-plastic waste is cleaned and crushed to remove pollutants and attachments.

Grinding treatment: The shredded aluminum-plastic waste is being pulverized to facilitate the next step of processing.

Electrostatic separation: Use special electrostatic separation equipment to separate aluminum-plastic waste powder, that is, to completely separate the aluminum and plastic powder inside.

Dust removal: Pulse dust removal device is used to ensure that no secondary pollution will be caused to the environment during the entire production process.

Final processing: The separated aluminum and plastic can be further processed, such as smelting, compression, granulation, reprocessing, etc.

2. Advantages of equipment application range: Aluminum-plastic waste separation and recycling process equipment has the following advantages, which make it widely used in the field of waste recycling:

Efficiency: The aluminum-plastic waste separation and recycling process equipment can realize automatic operation, which greatly improves the sorting efficiency and processing capacity. Compared with traditional manual sorting, its processing speed is faster, saving labor costs and time.

Environmental protection: The process equipment adopts physical process for separation, without using chemical solvents or additives, which reduces the pollution to the environment. At the same time, recycling waste aluminum and plastic can also effectively reduce resource waste and reduce environmental load.

Accuracy: Aluminum-plastic waste separation and recycling process equipment adopts advanced sorting technology and sophisticated instruments, which can accurately separate aluminum and plastic and effectively remove impurities. This helps to improve the quality of waste recycling, guaranteeing the purity and reusability of recycled materials.

Economical: Aluminum and plastic are valuable recycled materials that can be reprocessed and sold after separation and recycling. Through the separation and recycling process equipment of aluminum and plastic waste, the value of waste can be maximized and economic benefits can be realized.

Wide range of applications: Aluminum-plastic waste separation and recycling process equipment is suitable for various types and scales of aluminum-plastic waste, such as aluminum foil waste, toothpaste skin, pharmaceutical plates, aluminum-plastic panels, Tetra Pak, etc.

Aluminum Plastic Separator Operation-Site

The aluminum-plastic waste separation and recycling process equipment developed and manufactured by SUNY GROUP has become an important tool in the field of waste recycling due to its high efficiency, environmental protection, precision and economy. Through this process equipment, aluminum and plastic can be effectively separated and recycled, reducing resource waste and environmental load. If you are interested, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231