Copper removing Machines from motor scrap

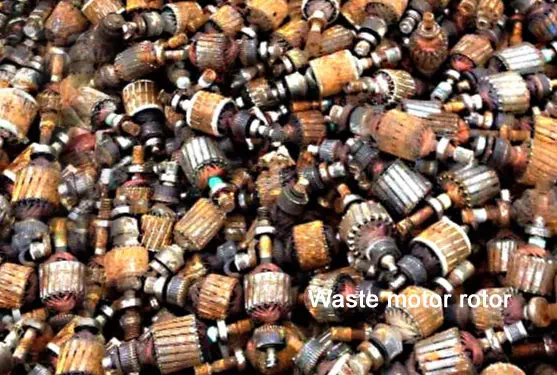

Scrap motor rotors, motor stators, and small motors are common scrap materials. Since they contain copper, iron, and aluminum, they have considerable recycling value, so higher requirements are put forward for the recycling of waste motor rotors. Using the principles of crushing, sorting, vibrating screen magnetic separation and specific gravity separation, copper is separated from non-metallic iron and other impurities. The separation purity can reach more than 99.8%, and there are basically no impurities. Recycling industry production lines, waste motor rotor processing production lines are recognized as ideal equipment for processing motor rotors.

Waste motor rotor processing production line For the working process of the waste motor rotor crusher, the manually pre-sorted waste motor stators, wire wraps and other materials are transported by conveyor to primary crushing and secondary crushing; The silicon steel sheet and the copper mixture are sorted; then the copper mixture is transported by the conveyor to the pulverizer for further crushing and refinement to obtain products with higher purity, and then transported by the conveyor to the air separator for sorting to obtain higher purity products. of copper particles and a small amount of non-metals. Therefore, considerable economic benefits are obtained. Due to the dust caused by crushing and sorting work, the system adopts negative pressure adsorption throughout the whole process and is equipped with a pulse dust removal device to effectively control the impact of dust overflow on the environment.

The principle of multi-layer beating and crushing of waste motor rotor processing production line will be able to solve the problem of motor rotor crushing. Improve the effect of crushing and selecting copper for the motor rotor. The waste motor rotor treatment production line adopts the resource recovery equipment that is physically harmless. The sorting machine separates the silicon steel sheet and the copper mixture; then the copper mixture is transported by the conveyor to the pulverizer for further crushing and refinement to obtain products with higher purity, and then transported by the conveyor to the air separator for sorting to obtain High purity copper particles and a small amount of impurities. Therefore, considerable economic benefits are obtained.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231