Copper wire scrap separating machine

Copper wire scrap separation machine is an efficient and environmentally friendly machine that plays a vital role in the waste wire recycling industry, which helps to effectively process waste copper wires and convert them into useful resources, reducing the impact on natural resources demand, while reducing adverse impacts on the environment. Copper wire waste separation machine is one of the key technologies to promote environmental protection and sustainable development.

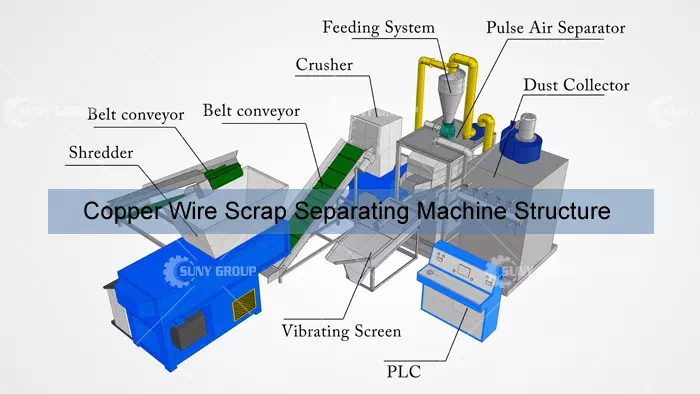

Working principle of copper wire scrap separation machine

The copper wire waste separation machine adopts advanced physical separation technology, which mainly includes the following steps:

Material shredding: First, the mixed waste wires are pre-treated, including shredding and cleaning. These waste wires usually contain insulation, metal and other impurities, and the shredding process separates the insulation on the outside of the wire and exposes the metal inside.

Vibrating screening: The broken wires are sent to the vibrating screening machine, and the metal particles and impurities of different particle sizes are separated through screens with different apertures. This step ensures that only compliant metal particles enter the next step of the separation process.

Gravity Separation: During vibratory screening, the heavier copper particles will settle down, while the lighter impurities will be blown away by wind or other auxiliary equipment. This gravity-based sorting allows the copper particles to be collected individually, ready for subsequent steps.

Electrostatic Separation: Next, electrostatic separation technology is used to further separate fine copper particles and insulating materials. By electrostatically charging the material, the copper particles and the insulating material will be separated due to the difference in electrical properties, thereby achieving a more accurate sorting effect.

Application of Copper Wire Scrap Separation Machine

Copper wire scrap separation machine has a wide range of applications in the field of waste recycling. It provides an efficient and environmentally friendly solution for the recycling of waste wires, making a positive contribution to sustainable development.

Reuse of resources: Through the copper wire waste separation machine, a large number of waste wires can be efficiently processed, and valuable copper resources can be recovered from them. This recovered copper can be used to make new wires and cables, saving virgin resources and reducing the need for mining.

Environmental protection: If the insulating materials and other harmful substances in the waste wires are disposed of randomly, they may cause pollution to the environment. Through the treatment of separate machines, the impact of waste on soil and water sources is effectively reduced, which helps to maintain ecological balance and environmental health.

Economic benefits: The waste recycling industry is a booming economic field. The use of copper wire waste separation machines improves the efficiency of waste recycling, creates employment opportunities, and promotes sustainable economic growth.

Technological progress: The application of copper wire waste separation machines has promoted the development of waste recycling technology and stimulated more research and innovation on waste recycling and resource reuse.

Although copper wire scrap separation machines have excelled in the field of waste recycling, there are still some challenges. For example, different types of waste wires may have different structures and characteristics, so the parameters of the machine and the processing flow need to be adjusted in a targeted manner. In addition, the insulation materials in waste wires are constantly updated, requiring continuous improvement of technology to adapt to new materials. In addition, the energy efficiency and processing efficiency of the machine are also aspects that need to be continuously optimized. SUNY GROUP, as a professional manufacturer of wire waste recycling equipment, has rich experience and perfect technology. It adopts effective debugging for different wire waste materials of customers to ensure that the user's wire waste recycling rate reaches 99% and above.

Copper wire waste separation machine is one of the key technologies to promote environmental protection and sustainable development. Through advanced physical separation technology, it effectively separates copper resources from waste wires, providing important support for resource reuse. Applying this technology can not only reduce dependence on natural resources, but also help protect the environment, create economic benefits and promote technological progress. However, we also face a series of challenges, which require continuous improvement of technology to make it more adaptable to diverse waste recycling needs. The development prospect of the copper wire scrap separation machine is still broad, and it is believed that driven by the continuous advancement of science and technology, it will play a more important role in the future.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231