Detailed introduction of scrap copper and aluminum radiator crusher

Every year, a large number of waste products such as household air conditioner radiators, heating radiators, and automobile air conditioner radiators are produced in the world, which not only pollutes the environment but also causes waste of resources. high. Faced with the mountains of copper-aluminum water tanks, electronic waste, automobile dismantling waste, household appliance dismantling waste and other composite materials, which are large in volume and low in value, is it more reasonable to dispose of them? The electronic waste formed after the fine dismantling of the automobile water tank is mainly composed of copper tubes and aluminum foil wastes. The copper content of the copper tubes can generally reach more than 97%. The air-conditioning radiator water tank is physically broken to sort copper and aluminum.

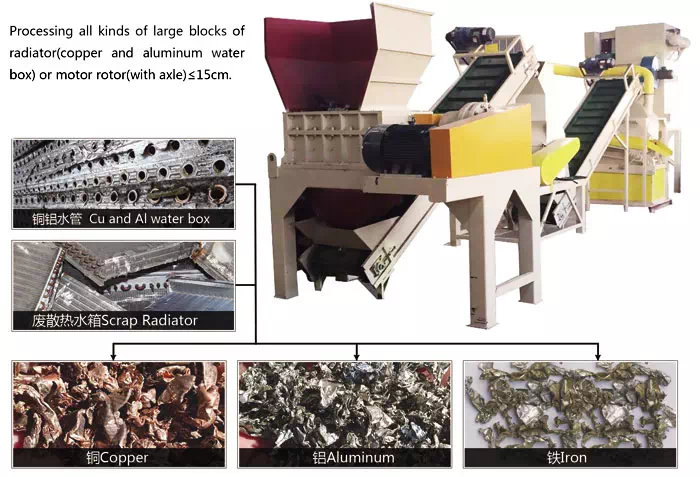

The copper-aluminum radiator recycling production line from Suny Group, this production line is used to separate copper, aluminum and iron contained in waste copper-aluminum radiators to realize resource regeneration and play a recycling role. Dust removal efficiency: ≥99.9%, iron separation efficiency; ≥99%, copper and aluminum metal separation efficiency: >98%.

The working principle of the copper-aluminum water tank crusher and separator: the dismantling and separation of the copper-aluminum water tank has basically replaced the labor by the machine. , Aluminum is thrown elsewhere by the vibrating screen due to its low density, and what is left is broken copper.

What are the complete sets of equipment for the copper-aluminum water tank crushing and separating machine, the dismantling and recycling device for the waste water tank radiator, including the crusher, conveyor belt, second crusher, second conveyor belt, magnetic separation device, vibration separation device, suction Dust pipe and dust collector, the crusher is provided with a two-shaft pair-roller shredder, and the second crusher is provided with a roller structure; one end of the conveyor belt is connected to the hopper of the crusher, The other end is connected to the feed hopper of the second crusher; one end of the second conveyor belt is connected to the discharge hopper of the second crusher, and the other end is connected to the specific gravity sorting device; the magnetic separation device is arranged on the second conveyor belt Above; the dust suction pipe is provided with at least four branch pipes.

This production line has been developed by our company for many years. Compared with Oujia's processing technology, our processing process has lower metal loss, minimizes the number of times the material is broken, and ensures that the material is separated in a large state, thereby reducing the metal powder. generate and improve recycling efficiency.

The crusher adopts the design of two shafts and rollers, which has low noise and large torque, and can crush large-volume radiators.

The cutting tool of a breaker is made of alloy tool steel, which is processed by a special process and has a designed service life of about one year.

The use of bipolar specific gravity separation improves the separation accuracy, and the purity of the separated copper, aluminum and iron is more than 99%.

The treatment process adopts a closed type and is equipped with a dust collection system, which effectively controls the dust overflow.

The above is the relevant introduction of the copper-aluminum radiator recycling production line. As a professional recycling equipment manufacturer, Suny Group has rich experience and advantages in solid waste recycling. If you have any needs, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231