How Are Blister Packs Recycled?

Commonly used to package pharmaceuticals, electronics, and consumer goods, blister packs consist of a plastic cavity that contains the product and a clear plastic or aluminum foil lid. While blister packs offer convenience and protection, they can present challenges when it comes to recycling due to their complex composition. In this article, we'll explore the process of recycling blister packaging and the various techniques used to recover its valuable materials.

Blister packaging waste

Composition of blister packs

To effectively recycle blister packs, it is crucial to know their contents. Most blister packs consist of multiple layers of materials including plastic, aluminum and paper. The plastic layer is usually made of polyvinyl chloride (PVC), polyethylene terephthalate (PET) or polystyrene (PS). These layers are often combined with aluminum foil to enhance barrier properties and protect the product.

Recycling of blister packs

Blister packaging recycling process

The recycling process starts with collecting and sorting the blister packs. These bins are usually located at recycling centres, supermarkets or pharmacies. After collection, the blister packs are sorted. Automated sorting technologies such as optical scanners and infrared sensors are used to separate blister packs from other recyclable materials based on composition and colour. This step helps ensure that only suitable blister packs make it to the next step of recycling.

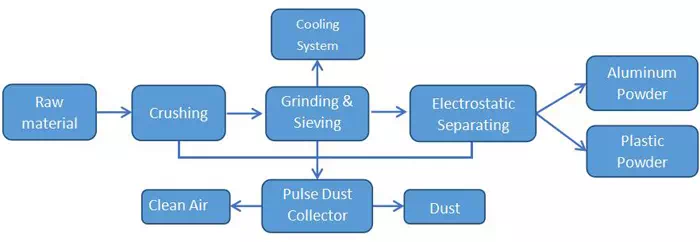

After removal of the product, the blister pack is ready for material separation. Various techniques can be employed to separate the different components of the blister pack. For example, the aluminum-plastic separation and recycling production line developed and manufactured by SUNY GROUP includes mechanical crushing, grinding, separation, and other processes.

Next, the plastic parts are further reduced in size by shredding or pelletizing. Shredders break down the plastic into smaller pieces, which can then be separated by size by passing through a screen. This step ensures that the plastic fragments are uniform in size for subsequent processing.

In mechanical separation, blister packs are crushed or ground to break them into smaller pieces. This process helps separate the foil or plastic lid from the plastic cavity. Then an electrostatic separator can be used to completely separate the aluminum powder and plastic inside to obtain pure aluminum and plastic.

Blister pack reuse

Plastic and Aluminum Powder

Materials separated from blister packs, such as aluminum foil and plastic scraps, can now be recycled. Aluminum can be melted and processed into ingots, which are used to make new aluminum products. Depending on its composition, plastic scrap can be recycled into various products or used as raw material for other plastic manufacturing processes.

Recycled plastic pellets or flakes can be used in a variety of applications, such as the manufacture of new plastic products, including packaging materials, construction materials and consumer goods. Some recycling facilities are also exploring innovative technologies, such as extrusion and injection molding, to create new products directly from recycled plastic scrap.

Due to its complex composition, recycling blister packaging presents both a challenge and an opportunity. However, with SUNY GROUP's progress in aluminum-plastic material sorting technology and material separation technology, the recycling technology and equipment solutions for blister packaging are becoming more and more mature. At present, in addition to blister packaging, other aluminum-plastic waste, such as toothpaste Leather, Tetra Pak, aluminum-plastic panels, etc., we also have rich recycling experience and technology, if you have any needs, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231