How to extract and recycle precious metals in e-waste?

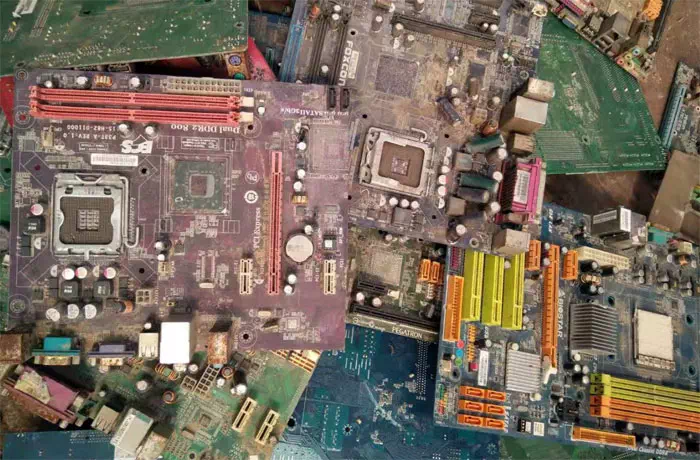

Gold-containing components can be picked out from spare parts such as computers, and gold can be extracted. In 1 ton of electronic boards, 130 kilograms of copper, 20 kilograms of tin, and 0.45 kilograms of gold can be separated. "E-waste" has become an industry that hides huge profits.

The precious metals in e-waste scrap are becoming more and more valuable, mainly because:

(1) Humans have produced a large amount of precious metals (gold, silver, platinum, palladium, rhodium, iridium)

(2) The resources of precious metals are scarce, especially gold and silver industry reserves are less.

(3) The precious metal content is much higher than that of the original ore, generally several hundred times or more.

Sources of precious metals in e-waste:

(1) Gold-containing electronic components, video recorders, record players, measuring instruments, analyzers, computers and some contacts, leads and circuit boards of instruments and electrical appliances also contain gold.

(2) All kinds of gold-containing alloys, the content of gold in the alloys is very high. There are also many low-gold alloys that are more easily forgotten after use for the gold in them, and are only recycled as general metals.

(3) The gold content of various types of waste gold plating solutions varies greatly.

(4) Jewelry waste, anode slime, batteries, solder alloys, dental alloys, gold-plated devices and all devices involving the use of gold, such as chemical, electronics, medicine, electroplating and jewelry, contain gold.

E-waste precious metal extraction process:

SUNY GROUP has developed a series of high leaching rate, high recovery rate, low-cost, environmentally friendly precious metal separation and extraction technologies in electronic waste recycling, and successfully realized industrialization. The research and development of the extraction of precious metals from precious metal-containing minerals, smelting waste residues, electronic waste, and medical waste has achieved effective separation and extraction of gold, platinum, silver, copper, nickel and titanium, with considerable economic benefits. In particular, the combined acid-base leaching process of precious metal-containing minerals, tailings and smelting waste residues realizes the comprehensive utilization of silicon, iron, aluminum, magnesium, copper, titanium, zinc and other elements while separating and extracting precious metals, which is environmentally friendly and efficient. Advantage.

If you have a demand for the extraction of precious metals from e-waste, please feel free to contact us and we will reply in time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231