How to recycle waste plastics?

Due to the rich resources of waste plastics, the low cost of recycling, and the low investment in equipment, the recycling of old plastics can avoid polluting the environment on the one hand, and can also obtain certain economic benefits. So what is the process of waste plastic recycling?

The first step: sorting and collecting waste plastics.

The waste plastics in the production and processing of plastics have a single variety, no pollution and aging, and can be collected and treated separately. Agricultural PVC film, PE film, PVC cable sheathing material, etc. can also be collected and processed separately.

Most of the waste plastics are mixed wastes. In addition to the complex types of plastics, they are also mixed with various pollutants, labels and various composite materials. For specific classification methods, please refer to the detailed introduction in the article "How to Classify and Identify Waste Plastic Recycling" by the following editor

The second step: crushing and sorting.

plastic electrostatic separator

Choose a suitable crusher according to its properties, and use various methods such as electrostatic method, magnetic method, screening method, wind method, specific gravity method, flotation separation method, color separation method, X-ray separation method, and near-infrared separation method to process waste plastics. Broken and sorted.

Among them, the plastic electrostatic separator developed and manufactured by SUNY GROUP can be used for material separation of plastic crushed materials, and adopts a dry physical separation method. Instead of traditional separation methods such as flotation, it is a faster and more accurate plastic separation equipment. It is suitable for the separation of ABS/PS/submerged PP/flame retardant ABS/flame retardant PS, PET, PVC, PA, PE, PA and other plastic materials.

Features

1. High compatibility, low requirements on materials, able to adapt to many different plastics. Plastics that cannot be separated by traditional sorting methods such as flotation can also be easily sorted by electrostatic separators.

2. There are many materials in a single sorting, and it can sort 2-4 kinds of plastics at the same time. Compared with the traditional sorting method, equipment sorting can effectively separate plastics with mixed materials.

3. The sorting purity is good, the equipment adopts multiple separation modes, and the sorting accuracy is about 99%.

4. The physical sorting method uses the difference in the charging properties of plastics as the sorting principle, and uses the electrostatic separation method. The operation is safe and there is no discharge of waste gas, waste water and other pollutants. It is an environmentally friendly separation equipment.

5.PLC operating system, easy to use and easy to use.

The third step: resource recycling.

1. Manufacturing of fuel oil. Use such as food bags, waste woven bags, beverage bottles, plastic soles, wire and cable skins, foam lunch boxes, plastic toys, etc. to produce high-quality 90# fuel oil, and 1 ton of waste plastics can produce about half a ton of oil.

2. Production of waterproof and antifreeze glue. Using foamed plastic waste as the base material, it produces multi-variety, multi-purpose indoor and outdoor building decoration water-resistant adhesive paste glue series products under special formula and process conditions. Each ton of waste can produce several tons of finished glue

3. Preparation of aromatic compounds. The method is to heat waste plastics such as PE and PP to 300°C to decompose them into carbohydrates, and then add catalysts to synthesize aromatic compounds such as benzene, toluene and xylene. When reacting at a temperature of 525°C, 70% of waste plastics can be converted into useful aromatic substances. These substances can be used as raw materials for chemicals and pharmaceuticals, and fuel improvers for gasoline, etc., and have a wide range of uses. The remaining components can be converted to hydrogen and propane.

4. Prepare multifunctional resin glue.

5. Use aluminum-plastic automatic separator for aluminum-plastic composite materials. The aluminum-plastic packaging will completely separate the aluminum and plastic in about 20 minutes. Each ton of waste aluminum-plastic packaging can separate 0.85 tons of recycled plastics and 0.1 tons of waste aluminum.

6. Fireproof decorative board.

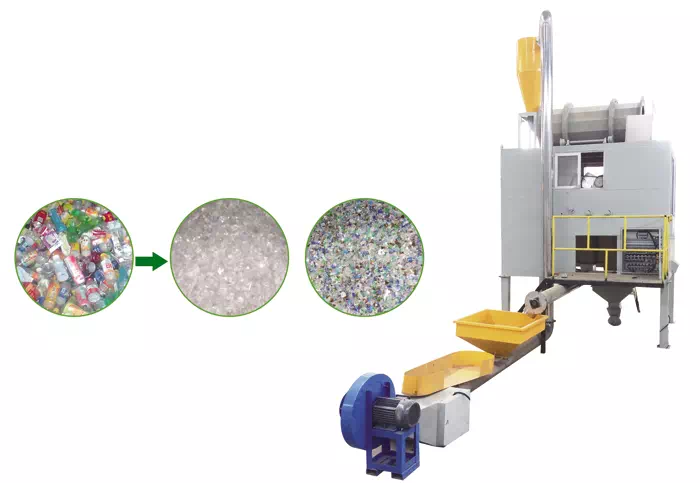

7. Using special granulation equipment, plastics such as waste polyethylene and polypropylene can be crushed-cleaned-heated and plasticized-extruded to process and produce recycled granules that sell well in the market.

8. The production of Keleu Wang used on the surface of houses has very strong anti-leakage performance.

9. Production of plastic woven bags

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231