Introduction To The Advantages Of Double Shaft Industrial Waste Shredder

SUNY GROUP dual-shaft industrial waste shredder adopts imported bearings, alloy steel spindle, high-strength knives and integral knives, equipped with intelligent monitoring system, centralized lubrication system, hydraulic pressing device, specially designed for shredding scrap metal, tires, household appliances , plastic, leather and other complex industrial waste material design. The simple structure combined with the sturdy materials and various operation auxiliary systems give it an absolute advantage in terms of comprehensive cost-effectiveness such as operation convenience, operation stability, crushing effect, and service life.

Intelligent monitoring system

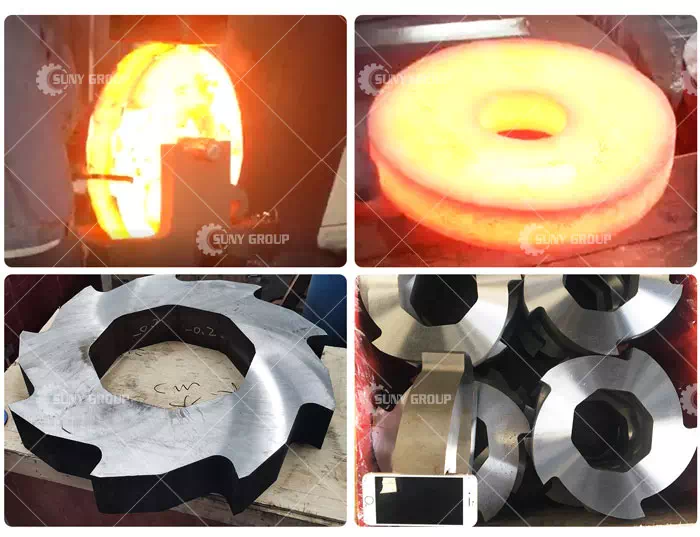

Dual Shaft Shredder Knives

The intelligent monitoring system has the functions of real-time monitoring, automatic memory, intelligent reminder, intelligent protection, automatic fault diagnosis, etc., and the operation of the equipment is more assured; through the visual Siemens PLC touch screen, friendly human-computer interaction is realized, and the on-site operation is more worry-free.

Anti-winding device

Specially designed a fixed knife structure that can be disassembled independently and anti-winding, which solves the problem that when disposing of industrial waste on a large scale, the material flow is not smooth due to plastic, fabric, fiber, etc. winding the moving knife, which affects the smooth operation of the equipment; Fixed knives are installed individually and fixed in groups, which can be flexibly interchanged according to wear differences, extending the service cycle.

Double shaft shredder customer site

Integral knife box

The tool box is processed by the overall annealing process, and the high-precision 4-axis machine tool is processed at one time. It has stronger stability and bearing capacity, is not easily deformed for a long time, and has a longer service life; the tool box can be disassembled up and down, and the maintenance is fast and convenient.

Centralized intelligent lubrication system

The centralized intelligent lubrication system can set the automatic oil injection cycle and each oil injection amount, reduce the manual operation content, and improve the operation stability of the equipment.

Hydraulic pressing device

The hydraulic auxiliary pressing device can be selected to deal with the materials that are not easy to be shredded and improve the comprehensive adaptability of the equipment and materials; the frequency and stroke of the feeding and feeding of the feeder can be adjusted according to the actual working conditions.

High-quality core parts

The shaft and the tool are made of imported alloy steel, which greatly improves the strength, toughness, wear resistance and corrosion resistance; the imported bearings are protected by a quadruple sealing structure, which is more waterproof, oil-proof and anti-fouling.

SUNY GROUP is a professional manufacturer of waste recycling equipment. In terms of shredder manufacturing, it can adopt customized production according to customer needs to meet customer recycling needs. If you need or want to know more, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231