Metal shredder structure principle and purchase

Metal shredder mainly consists of shredding blade set, bearing box, box support, feeding system, power system, electrical control system of the machine. It is mainly used for shredding light metal with certain strength, increasing its stacking density for transportation and recycling. Shredding objects such as metal barrels, refrigerators, cars, scrap steel, steel furniture, etc.

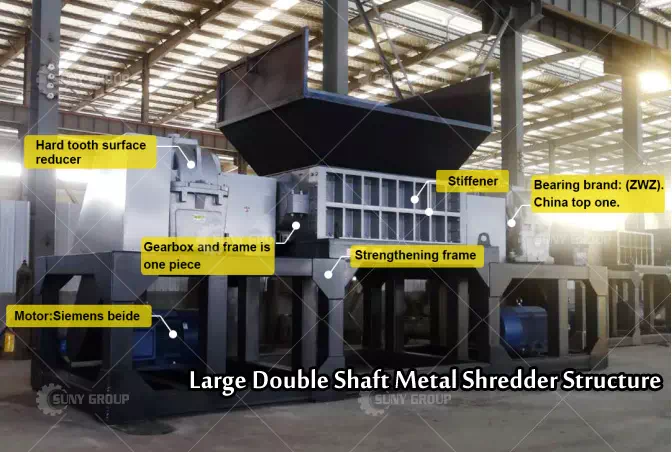

Structure principle:

Metal shredder in the working process through the motor connected to the reducer will be a stable power into the spindle, in the spindle traction through the shredder blade fixed on the spindle will enter the metal shredder cavity of the scrap metal for jamming, in the blade jamming process of continuous downward pressure of the material is involved in the gap between the two axes, through the double shaft tearing effect of the material to achieve the crushing effect, after the crushing of the material usually presents After crushing, the material is usually in the form of strips or flakes, which are filtered out from the bottom of the equipment and transferred by conveyor belt into the material pair for other equipment to be processed centrally or collected directly.

1、Metal shredder special dynamic fixed blade

The shredder blades are divided into fixed and dynamic knives, fixed knives through the internal hexagonal jamming holes fixed in the shredder spindle to crush the material processing.

2. Metal shredder spindle

Positive hexagonal interface shaft, linked to the reducer through bearings and couplings.

3、Metal shredder chassis

Mainly for the installation of bearings and spindle fixed to provide support, while providing a more enclosed space for the four-axis or dual-axis linkage crushing.

4、Metal shredder bearings

Through the internal pressure-bearing cylinders to reduce the friction during the rotation of the spindle, thereby reducing torque loss.

5, metal shredder reducer

Through the reducer to adjust the motor output speed, while reducing the spindle impact brought about by the motor damage, increase the spindle torque.

6, support frame, main body, motor, hopper, power distribution cabinet, electromagnetic reversing valve, and other control and other accessories.

Metal shredder purchase:

① Determine the maximum size of the material you crush when choosing a machine

② The material of the material

③ Size of material required after crushing

④ Production requirements

⑤ If possible, it is best to prepare a certain amount of material for testing, in order to equipment does not reverse the appropriate (reverse means that the power is small)

The above is the introduction of the metal shredder, customers in the purchase of metal shredder must be based on their own actual situation, if the conditions can visit the manufacturer to test the machine, in order to choose the right shredder equipment.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231