Plastic crushing and separation solutions

Waste plastic products for better recycling, will generally take the crushing process, to facilitate the removal of some impurities in the plastic, for the next recycling to provide convenience, but also to improve the value of recycling.

The crushed plastic will face two problems, after solving these two problems, the waste plastic can be recycled to obtain better value benefits, the two problems: one is the waste plastic crushing material contains some impurities, the second is the crushed plastic products will be a mixture of different materials plastic.

Next, it is about the recycling program of these two problems.

For impurities in waste plastics, the common assembly line scheme is as follows.

Feeder → brine bleaching tank → plastic crusher → clear water bleaching tank → dumping machine → drying machine → plastic sorting machine

Through this assembly line, the process of impurity removal is as follows

Start the line, the feeder begins to provide uniform material delivery for the line to maintain a stable working intensity; then, the material passes through the brine bleaching tank to remove the metal, stone and other large density heavy material sink bottom; next, if the plastic block is too large or uneven then it passes through the crusher to crush once.

After that, through the clear water bleaching trough, at this time, the plastic materials with different densities can simply be separated; then it is dumped and dried; because next our silica gel machine needs the material to be dried before sorting, through the silica gel machine, it can remove some impurities such as rubber silica gel from the plastic.

The purity of the plastic obtained at this time can reach more than 99%, which means that it can be sold, and the price will be good.

This assembly line can remove and recycle most of the plastic. If the impurities in the plastic are more complicated, the equipment can be adjusted according to the needs and suggestions.

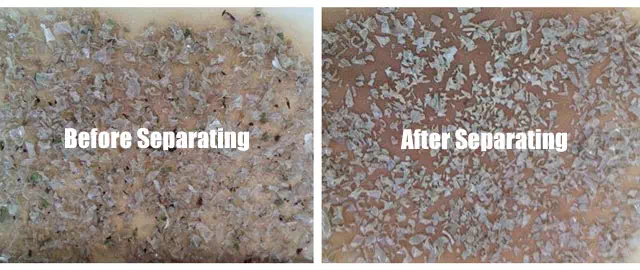

Then comes the separation of mixed plastics.

As mentioned above, the use of clear water flotation method like clear water floatation tank is also able to separate plastics in a simple way. However, this is also a simple separation, if the density of the two plastics is about the same, then this method will not be able to be separated.

To separate different plastics, the equipment used is the plastic electrostatic sorting machine, which is a kind of sorting using the different electrical properties of different plastic materials, is a purely physical plastic separation equipment, no three wastes and other environmental problems.

Electrostatic sorting machine can separate mixed plastics, such as ABS/PS/submerged PP, ABS/ABS alloy/PC, PS/PET/PVC, PA/PE/PO, etc. It can sort almost everything that plastic recycling sites need to sort.

Similarly, the sorting purity of plastic electrostatic sorting machine sorting is above 98%, and after sorting, it is able to be sold.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231