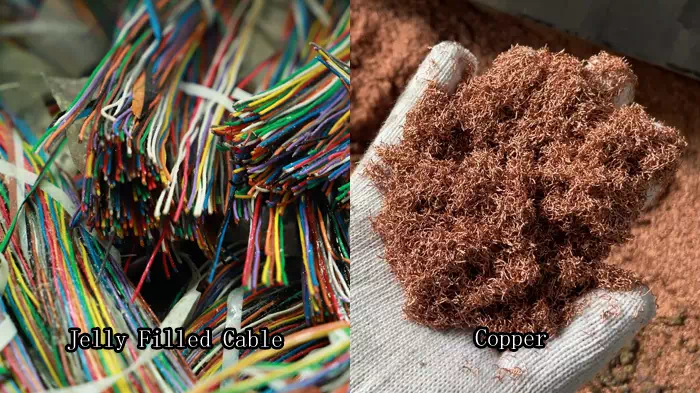

How to Efficiently Recover Copper from Contaminated Scrap Wires?

In our daily life or in related industries, we often see a lot of waste wires and cables, because they contain a lot of copper, so they have a very high recycling value. For some relatively clean waste wires, we can directly use waste wire recycling equipment The copper inside is separated. However, there are also some waste wires contaminated by oil, which need to be degreased before copper can be recovered. This article will focus on the process of effective copper recovery from contaminated wire scrap, the machinery involved, and the rationale for how it works.

Jelly Filled Cable Recycling

The recovery process of copper from oily waste electric wires generally includes the following steps:

Collect: Collect all scrap wires. The process usually involves businesses and individuals selling scrap wire to recycling plants.

Primary shredding: Use a single-shaft shredder to shred waste wires.

Degreasing: Put the broken waste wires into the prepared degreasing solution and stir to remove the surface oil.

Degreasing Solvent Test

Pulverization treatment: Use a pulverizer to pulverize the cleaned waste electric wires.

Separation: The granular material obtained after crushing is separated into copper and plastic. This is usually achieved by water sieving, where the lighter insulation is washed away by the current, leaving behind the heavier copper particles.

Critical Recovery Equipment

Oil pollution line recovery equipment

Several types of machinery are critical to the process of copper recovery from wire scrap:

Crusher/shredder: used to cut waste wire into small pieces or pellets. This is an important step in preparation for the separation process.

Decontamination solution configuration: This step is used to remove oil stains in waste wires, which is a key step in the treatment of contaminated waste wires.

Water screening: This is an efficient separation method, which is very effective for the recovery of cleaned waste wire particles.

The rationale for copper recovery from wire scrap is based on the differences in physical properties between copper and insulating materials:

Size reduction: By cutting the wire into small particles, the surface area between the copper and the insulation is increased, making it easier to separate the two.

Air Separation: Copper is much heavier than most insulation materials. Thus, when an airflow is applied to the granular material, the lighter insulating material can be blown away, leaving copper particles behind.

Electrostatic Separation: Copper and most insulating materials have different electrostatic properties. This allows them to separate in an electric field, as the insulating material will be attracted to one electrode and the copper will be attracted to the other.

Compared with the recycling of ordinary waste wires, oily wires require an additional process of oil pollution treatment. Recycling copper from contaminated waste wires is a sustainable and profitable practice that contributes to the circular economy. With the right equipment and an understanding of the fundamentals, the process can be efficient and effective.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231