How to Recycle and Recycle Scrap Lithium Batteries?

You must have heard such a sentence, there is no absolute garbage in the world, just raw materials that have not been used well. Is garbage a misplaced resource? Today, let's take a look at how waste lithium batteries can be reused.

First of all, it is necessary to judge whether the waste lithium battery has electricity or no electricity. When the waste lithium battery is checked, it has electricity. For example, the average service life of the power battery is 5-8 years, and its performance decreases with the increase of charging times. The capacity decays to less than 80% of the rated capacity, and the power battery is no longer suitable for electric vehicles. However, after testing, maintenance, and reorganization, the retired batteries can still be further utilized in many fields such as energy storage, distributed photovoltaic power generation, household electricity, and low-speed electric vehicles. When the battery cannot be used in cascade, it needs to be recycled and disassembled for resource processing.

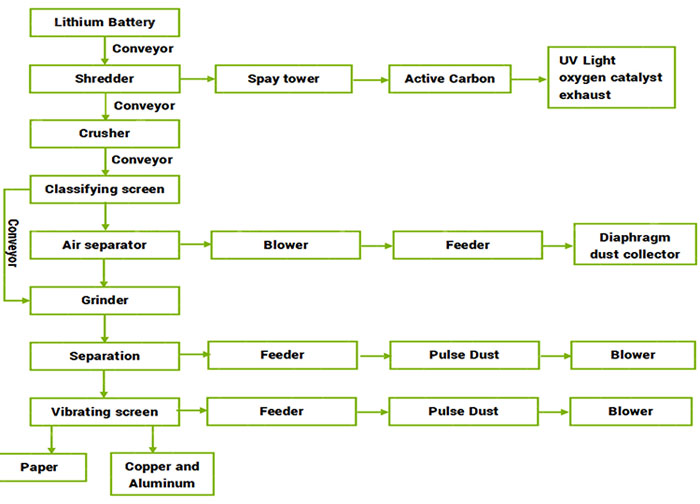

Recycling treatment is generally to recover the battery pole pieces through the method. The whole system generally includes a primary crusher, a conveyor, a hammer crushing device, a negative pressure extraction device, a collection hopper, and a screening device. Among them,

1. The primary crusher is used for primary crushing of the material to reduce the size of the material. The material refers to the pole piece of the dry battery, and the original size is generally 200×140×3mm; (the primary crusher 100 is a double-shaft tearing machine. Crusher, the collection hopper is a cyclone collection hopper.

2. The feed end of the conveyor is connected to the primary crusher, the discharge end of the conveyor is connected to the hammer crusher, the discharge end of the conveyor is higher than the feed end of the conveyor, and the material crushed by the primary crusher is Transported to hammer crusher for further crushing;

3. The hammer crusher is used for beating and crushing the materials crushed by the primary crusher, so that the materials are in powder form with a diameter of about 2-3mm, which is convenient for further sorting of the materials; (hammer crushing device one hammer type Crusher and two-hammer crusher, the one-hammer crusher is arranged above the two-hammer crusher, the feeding end of the one-hammer crusher is connected with the discharging end of the conveyor, and the feeding end of the two-hammer crusher is The end is connected with the discharge end of the one-hammer crusher, and the negative pressure extraction device is connected with the discharge end of the two-hammer crusher.

The material is beaten and crushed by a one-hammer crusher to further reduce the size of the material; the material is beaten and crushed twice by a two-hammer crusher to crush the material into powder. By beating and crushing twice, the fineness of material crushing can be improved, and the material is beaten into powder and granular, which is convenient for material recovery, saves recycling space, and indirectly reduces the cost of logistics, and powder and granular materials are convenient for subsequent reuse.

4. The negative pressure extraction device is arranged below the collection hopper, and the negative pressure extraction device is connected with the hammer crushing device to negatively extract the materials crushed by the hammer crushing device into the collection hopper, and collect powder and granular materials in the collection hopper; The negative pressure extraction device is a high-pressure fan, which uses the high-pressure fan to extract the material under negative pressure into the collecting hopper. The battery pole piece processing and recycling system also includes a shut-off fan, which is connected to the discharge port of the collecting hopper and arranged above the screening device to control the materials in the collecting hopper to enter the screening device.

5. The screening device is arranged below the discharge port of the collecting hopper to screen the materials crushed by the hammer crusher to obtain copper particles, aluminum particles and black powder respectively. The screening device is a vibrating screen, and two layers of screen meshes are arranged up and down in the vibrating screen. Among them, the screen mesh located in the upper layer is 60 meshes; the screen mesh located in the lower layer is 120 meshes. Different materials are collected separately. Specifically, when the materials are sieved by the vibrating screen, the aluminum particles stay on the upper screen, the copper particles remain on the lower screen, and the black powder falls under the lower screen, so as to realize the three separation of matter. The power of the vibrating screen is 1.5KW, the slope of the vibrating screen is 3°, and the discharge is relatively gentle.

The pole piece processing and recycling system further includes a water supply device, which is connected with the hammer crushing device to cool down the hammer crushing device. The water supply device is connected with the one-hammer crusher and the two-hammer crusher respectively, mainly to cool the bearings in the one-hammer crusher and the two-hammer crusher, so as to prevent the high-temperature heat generated when the bearing rotates at high speed, which will affect the bearing life.

6. The dust removal device includes a pulse dust collector, a second-off fan and a dust exhaust fan. Among them, the pulse dust collector is connected with the air outlet of the dust removal duct, and the air inlet of the dust removal duct is respectively connected with the hammer crushing device and the screening device; the second off fan It is arranged below the ash hopper of the pulse dust collector, and the dust exhaust fan is connected to the air outlet of the pulse dust collector 810 . The dust gas is purified by the pulse dust collector, the dust is collected by the ash hopper, and the standard gas is discharged by the dust exhaust fan.

Through the above introduction, I believe that you have a certain understanding of the recycling and reuse of lithium batteries. The recycling of scrapped lithium batteries can not only reduce pollution, but also effectively use it to generate certain economic benefits. With the continuous development and utilization of the lithium battery industry, the reuse of scrapped lithium batteries will also become an important recycling industry. If you have related questions or questions, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231