Shredder blade working principle

To understand what is a shredder blade and its function, the first thing to understand the structure of the shredder and its use.

The shredder is mainly composed of hopper, shredding chamber, knife frame, screen, hopper, motor and so on. The range of shredding is relatively wide. The most common ones are straw shredding, scrap shredding, packaging industry shredding, chemical fiber recycling shredding, etc. Usually, shredding is used for cleaning or sorting and reprocessing.

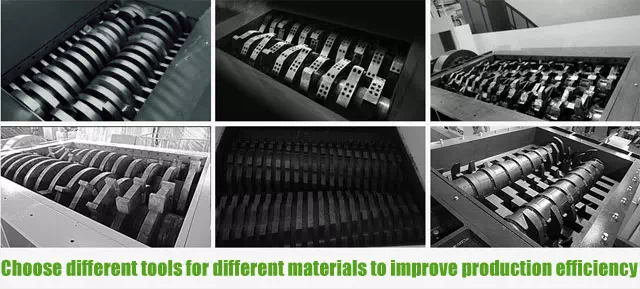

There is a wide variety of blade materials, different materials, different processing processes and different specifications, resulting in completely different properties and different processed products. The main raw materials are T10, 9CrSi, 6CrW2Si, Cr12MOV, SKD 11, D2, W18Cr4V, Fenggang and other domestic imported materials.

Shredder blades are also called plastic shredder blades, mainly including powder plastic shredder blades, plastic film seal cutting blades, plastic shredder blades, alloy plastic granulator blades, steel seal cutting blades, plastic granulator rolling blades, plastic roller cutting blades, granulator hobs, plastic shredder screens, chemical fiber recycling shredding machinery blades, high-speed shredder blades. Feed, Chinese medicine crushing, straw crushing knives, etc.

Plastic crusher blades, also called plastic machinery blades, are mainly used for crushing in the plastic and rubber industries. Like other blades, it requires precise geometric tolerances to ensure good assembly quality of the machine. It requires a choice of blade material chemistry that suits the different needs of the user and crushes different objects. It requires a proper angle of the blade, which not only keeps the blade sharp, but also gives the blade a certain strength that will not break the blade during use. It requires a good heat treatment process to achieve the right hardness and small blade internal stress, plastic crusher blade will not be deformed in the use of the process.

Plastic crusher blades are divided into crusher blades, powerful crusher blades and pelletizer blades.

Shredder blades

1. Shredder blade is also called plastic blade and plastic shredder blade, also known as water mouth blade in Guangdong region. It is a mechanical blade installed on the plastic shredder for plastic shredding.

2. Shredder blades are designed as flat blades, divided into shredding dynamic blades and fixed blades. Usually, a pair of shredder blades consists of five, three shredding movable blades and two fixed blades. The purpose of crushing plastic materials is achieved by the high-speed rotation of the shredding movable blades and the shearing of the fixed blades. The size of the crushed particles can be controlled by adjusting the crushing mobile blades.

3. Crusher blades are suitable for crushing a variety of ABS, PE, PP and other plastic materials for crushing and recycling. Shredder blades are divided into two types: all-steel blades and inlaid steel blades.

4. There are two types of shredder blades: all-steel blades and inlaid steel blades. Heat treatment hardness of HRC52-55 degrees. Technical requirements: impact resistance, wear resistance and high temperature resistance.

Power crusher blade

1:Power crusher blade is a mechanical blade installed on the power crusher for crushing large plastics.

2:The blade of Power Crusher consists of fixed cutter, claw cutter and spiral hob. The claw cutter and spiral hobber rotate the blade at high speed to crush plastic products with high production efficiency and uniform particles. The manufacturing process of the combined structure of the blades of the powerful crusher is more complicated than that of the flat knives.

3:Power crusher blades are suitable for crushing most plastic products with crusher blades, such as plates, pipes, profiles, sheets and packaging materials.

4:There are two types of Power Crusher Blades: all-steel blades and inlaid steel blades. Heat treatment hardness is HRC55-58 degrees. Technical requirements: impact resistance, wear resistance and high temperature resistance.

Pelletizer blade

1:Pelletizer blade, also known as pelletizer blade, is a mechanical blade installed on the plastic pelletizer for pelletizing plastic pellets.

2.pelletizer blade consists of fixed knife and pelletizing roller knife, generally a pelletizing roller knife and a fixed knife used in conjunction, pelletizing roller blade for the cylindrical oblique spiral blade, divided into all-steel hob and steel hob, the manufacturing process is complex. Fixed knife using flat knife design, processing and manufacturing is relatively simple.

2. Pelletizer blade is used for continuous rolling and cutting of linear plastic extruded by plastic extruder through the knife to achieve the purpose of pelletizing. The plastic pellets produced by the pelletizer blade are uniform and are necessary blades in the plastic pellet production industry.

3:The pelletizer blade is suitable for pelletizing most plastic pellets, such as polyethylene, polypropylene, PVC, polystyrene, acrylonitrile-butadiene-styrene copolymer, acrylonitrile-styrene copolymer, high impact polystyrene, etc.

4. Heat treatment hardness HRC58-62 degrees pelletizer blade, technical requirements: impact resistance, wear resistance and high temperature resistance.

SUNY GROUP is a professional solid waste recycling equipment manufacturer, has a wealth of experience and technical equipment in solid waste recycling, because in the solid waste recycling will generally use shredder, so we have a wealth of experience in shredder, crusher, shredder and grinding machine, according to customer needs, custom production. If you have relevant needs, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231