Solutions for solid lithium ion battery recycling

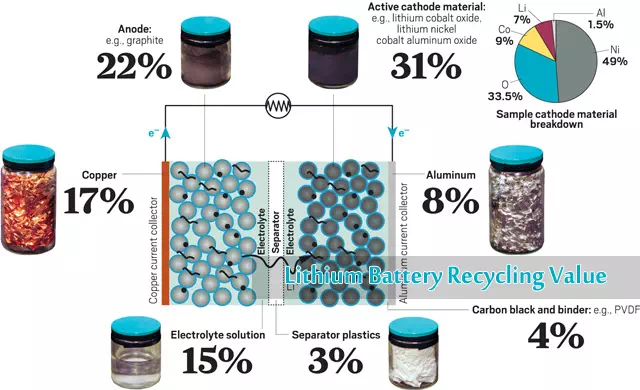

Waste lithium batteries can lead to heavy metal pollution if they are not disposed of, and the electrolyte solution can contaminate soil and water bodies. Generally, waste lithium ion batteries contain cobalt, lithium and nickel in proportions of 5% - 15%, 2% - 7%, 0.5% - 2% respectively, and also contain Cu, Al, Fe and other metal elements.

And with the sales of new energy vehicles rising year by year, the sales of power batteries, which are their core, have naturally also risen, thus promoting the booming development of the battery industry. However, this time, we are not talking about the battery industry, but the power battery recycling industry. Compared to a car, the life of a power battery is even shorter, generally maintaining around 4-8 years. Once the life is up, the battery must be replaced, and then the original old battery must be recycled. Therefore, the year-on-year rise in car sales and battery sales will mean an increasing amount of recycled batteries in the future.

Technical solutions for dismantling used lithium batteries:

The recycling of waste lithium batteries with the current process waste batteries must be pre-treated first, then the battery shredding, crushing, shredding, separation of diaphragm, shell and positive and negative fragments, through multiple crushing, wind selection, separation to get copper and aluminum mixed metal particles, to achieve the automated recycling of waste lithium batteries.

The lithium battery recycling process is simplified, with high output and high metal separation rate. The separation rate of waste lithium battery and black powder after crushing and sorting reaches more than 99% (according to the data assayed from the customer's site). A large number of cobalt, nickel, manganese, lithium and other chemical and rare mineral materials in the power battery are separated and purified to produce the raw materials for manufacturing batteries.

The efficiency of lithium battery dismantling crushing and sorting equipment for waste power battery diaphragm material can be higher than other brands by more than 35%, which can effectively enhance the recycling efficiency of end-of-life lithium batteries.SUNY GROUP's power battery recycling production line not only caters to the current development trend of power battery recycling, effectively regulates the requirements of power battery recycling production line, construction assembly and acceptance, but also well It is also a good way to implement the construction policy of green environmental protection, energy saving and emission reduction, to avoid power battery waste and to promote the green and intelligent ecological sustainable development of the industry. We can provide you with perfect lithium battery recycling solutions, if you need, welcome to contact us for consultation at any time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231