The main machines and equipment for aluminium-plastic separation and recycling

The new aluminium-plastic grinding and separating machine developed by SUNY GROUP can be used for low to medium hardness PVC aluminium-plastic, high density PE or other aluminium-plastic waste. After the aluminium-plastic separator has been crushed and sorted, the plastic and aluminium inside can be completely separated in order to recycle the resources.

This aluminium-plastic separation equipment is entirely mechanical in its separation. For example, aluminium-plastic tubes, also called aluminium-plastic hybrid tubes, have aluminium sandwiched between two layers of plastic. The aluminium-plastic separation plant is a machine that completely separates the aluminium-plastic tubes of aluminium-plastic composites into metal and plastic. The completely dry physical separation will not cause secondary environmental pollution and has good social and economic benefits.

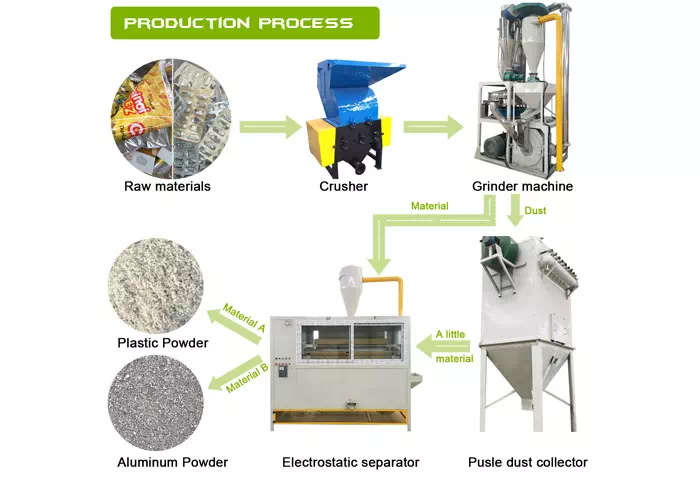

The aluminium-plastic separation equipment consists of a loading conveyor, crusher, mill, high pressure electrostatic separator and dust removal equipment.

① Aluminium-plastic crusher

The aluminium-plastic crusher is made of high quality tool steel and special knives for durability. The installation design of the knives can be adjusted by telescopic adjustment. The knives can be sharpened several times after being blunt and used repeatedly. The aluminium-plastic crusher has a stepped scissors design for the motorised knife base, which breaks down the cutting force and increases it exponentially. The blade holder is made of high quality tool steel, which is rigid and flexible, not easy to break and wear. It is fastened with 8.8 grade high-strength steel screws, with a strong and durable structure. The main body of the aluminium-plastic crusher is made of thick-walled high quality structural steel, which can prevent the mechanical properties of the material from being affected by long-term crushing. Aluminium-plastic crusher spindle and double end faces are machined in one pass by high precision three coordinate machine tools to ensure concentricity and perpendicularity error not more than 0.05MM. Each part is set with reference holes and surfaces for coarse and fine flow. Processing, parts interchangeability and high precision.

The main features of the aluminium-plastic crusher: large spindle slewing diameter, large crushing chamber capacity, unique knife shaft design for strong grip on hollow products, housing made of strong welded steel structure for wide versatility. Depending on the material to be crushed, we can offer different rotor designs and also crush sprues, tubes, profiles, plates, films and large sprues. The machine has many advantages such as economy, durability, easy cleaning and long service life. The blade material is made of wear resistant and tough SKD-11 alloy blades. Large hollow thin-walled plastic products, large hollow packaging boxes, large plastic boxes, plastic frames, refrigerator shells, TV plastic shells) and other plastic products do not need to be decomposed and crushed, and can be put directly into the crushing.

② Grinding machine.

The main function of the mill is to further grind the aluminium-plastic scrap after crushing in order to carry out the next step of material sorting.

Aluminium-plastic grinding mill features.

(1) Compared with similar mills, the output under the same power is greatly improved (20%-50% higher). Save energy consumption;

(2) Additional dust collection device, effectively reduce dust pollution;

(3) The design of the main fan outlet reduces the labour intensity of the operator;

(4) The main machine door cover can be opened, which is convenient for maintenance and knife changing.

③ Electrostatic separator

The advantage of the electrostatic separator is that there is no need to use chemicals to dissolve the waste and therefore no pollution to the environment. It can separate more than 97% of the gold, copper, aluminium and other metals from the plastic in the waste. In addition the multi-drum electrostatic separator solves the problem of separation yield and increases production according to the physical properties of the crushed material, the feeding method, the size and composition of the feed material and other working conditions. Different materials will have different separation effects. The electrostatic properties of the material should be tested before sorting, and the high voltage electrostatic sorter should be used to determine a better separation solution.

The electrostatic sorting machine can be widely used to separate and sort non-ferrous separated metals and non-metals. In general, most scrap products are composed of conductors and non-conductors, the emergence of electrostatic sorting machine to solve the problem of many metal and plastic complexes can not be separated. Especially in the recycling of aluminium and plastic scrap, it has become one of the most important components of aluminium and plastic sorting.

④ Dust removal equipment

Because of the physical and mechanical way of crushing and sorting, a certain amount of dust will be produced in the working process, therefore, the use of pulse dust removal equipment can effectively avoid dust pollution.

The above is the introduction of aluminium and plastic sorting, SUNY GROUP has rich experience and technical equipment in aluminium and plastic sorting, especially for Tetra Pak, aluminium blisters, aluminium and plastic sheets, etc., with targeted recycling solutions. If you have any questions or problems, please feel free to contact us for advice.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231