What are the recycling methods of used lithium batteries?

Lithium-ion battery packs can choose different utilization methods according to the degree of scrapping. Lithium-ion battery packs with a high degree of scrapping can be recycled and dismantled, and the available materials are collected and put into production and use; those with a low degree of scrapping can be selected for cascade utilization, put into use in areas with low energy demand, and reused according to the energy cascade.

1. Echelon utilization

The capacity cannot meet the current conditions of use, but the lithium-ion battery pack with long cycle life can be used in the field of energy storage through the mode of cascade utilization. Cascade utilization is an efficient and energy-saving recycling method suitable for used power lithium-ion battery packs, and achieves economic goals by extending the service life of power lithium-ion battery packs.

Generally speaking, when the capacity of the power lithium-ion battery pack is attenuated to about 80%, it will be eliminated, but the power lithium-ion battery pack at this time can still be used for energy storage equipment and put into commercial residential energy storage stations, electric vehicles Charging energy storage stations and telecommunications base stations and other places.

Regarding the recycling method of lithium-ion battery packs, in general, the use of cascade utilization method has higher resource utilization rate, because the cycle life of lithium-ion battery packs is long, and the energy storage utilization effect is better. However, the method of recycling lithium-ion battery packs on the market is not perfect, and it is not easy to implement this method in cascade. However, the market for lithium-ion battery packs is large, and the recycling market will also develop with it.

2. Raw material recovery

For lithium-ion battery packs that can no longer meet the needs of current applications, recycling can effectively utilize their residual value. For lithium-ion batteries with significantly reduced cycle life, renewable resources such as metal oxides, organic electrolytes, and plastic casings can be extracted. Resource recycling can effectively recover the cost of lithium-ion batteries, and has strong economics.

Cells account for 36% of the cost of power lithium-ion battery packs, and if the gross profit is deducted, cells account for as high as 49%; in consumer batteries, the cost of cells is even higher. In the cell, the cost of cathode materials rich in metal elements such as nickel, cobalt, and manganese accounts for 45%. Through the recovery of raw materials, metal elements such as nickel, cobalt, and manganese can achieve a recovery rate of more than 95%, and the recovery rate of lithium elements is also more than 70%, with significant economic benefits.

The lithium battery recycling process mainly includes three parts: pretreatment, secondary treatment and advanced treatment. A method for recycling waste lithium batteries, comprising the following steps: (1) using a dismantling device to shred the waste lithium ion batteries, and using a suction fan to separate and recover paper materials; (2) using a crusher for the product obtained in step (1) Carry out secondary crushing; (3) carry out magnetic separation of positive and negative products in the product obtained in step (2), and separate the mixture of copper and graphite; (4) adopt blade crusher for remaining product in step (3) Three times of crushing are carried out, and the mixture containing iron and lithium and the iron phosphate powder are separated by an air separator; (5) the separated mixture of copper and graphite is ground, and the copper powder and graphite are separated; (6) the separated The mixture containing iron and lithium is ground to separate iron powder and lithium powder. The whole process of the invention adopts an anhydrous environment, does not require any high temperature process, does not generate air pollution and water pollution, is relatively environmentally friendly, and has simple process and convenient operation.

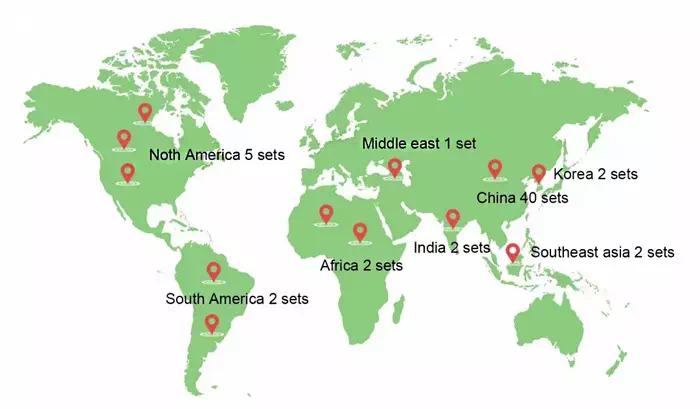

Clients of Lithium Battery Recycling Machine

The above is the relevant introduction about the recycling of end-of-life lithium batteries. As a professional manufacturer of lithium battery recycling equipment, SUNY GROUP has solved the problem of lithium battery recycling for many customers around the world, helping them to recycle and reuse lithium batteries. If you are interested or need, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231