What can a double shaft shredder do?

The double-shaft shredder equipment is mainly used to shred and process various large materials, such as: plastic templates, plastic buckets, films, waste cloth, old clothes, woven bags, etc. The shredded materials can be recycled directly after processing reuse. The specific shredded items include: scrap cars, tin cabinets, paint buckets, filters, bicycle racks, motorcycle racks, waste refrigerator freezers, plastic machine heads, wood, timber, etc. It uses the mutual shearing and tearing effect of the knives to realize the crushing and separation of materials. It has the following characteristics: low noise, low speed, high torque, high output, good stability, good effect and so on.

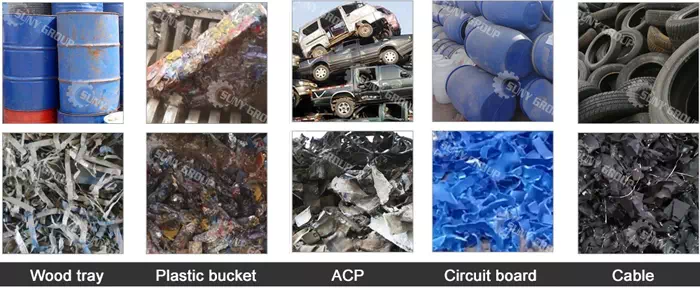

Double shaft shredder shreds materials

For example, waste refrigerators and freezers are bulky materials. If they are directly fed into the crusher, a very large crusher is required, which is too wasteful. First use a twin-shaft shredder to shred into small pieces, and then proceed to the next step of operation, the effect is greatly improved, and the output and effect are improved. The waste refrigerator double-shaft shredder adopts double reducers and double motors, and the thickness of the frame plate is thickened to make it stronger in compression resistance and firmness.

Working Principle:

The double-shaft shredder adopts two-shaft independent drive, so that during production, the material is pressed accordingly to achieve the automatic feeding function. The unique cutter shaft structure and four-corner rotary cutter can be used in the production process of low speed and high torque. , there will be no phenomenon of shaft winding or stuck equipment, thereby improving production efficiency. This equipment is suitable for crushing various tough and viscous materials.

The high speed of the double-shaft shredder reduces noise and reduces dust when shredding materials. According to environmental protection standards, it greatly improves the occupied land area and the environment. The blade of the double-shaft shredder adopts alloy plate blade, which has good hardness, high toughness, wear resistance and durability. The double-shaft shredder is easy to install, easy to operate, saves labor costs, reduces the output of raw materials, and improves work efficiency and output. The maintenance method of the machine must be carried out in accordance with strict requirements, so as to make use of the long-term service life of the machine.

The wide application of the shredder has brought a lot of economic development to our future recycling work, and also realized the functional requirements of full automation. The machine can feed materials at one time, and the gears inside the machine rotate these materials through high-strength extrusion. , instantly and easily crush the material, and the crushed waste will be discharged from the screen under the box. The design of the shredder is reasonable, the machine runs stably, the shredder loads and discharges quickly, the output is high, and it saves time and effort. It solves the traditional manual crushing method and speeds up the production.

In addition, different names such as metal shredder, plastic shredder, tire shredder, etc., are only designed by the manufacturer for the materials that customers need to process, with targeted adjustments and selection of cutting tools. The shredder equipment is designed to meet the needs of customers and protect the interests of customers. The difference in model is of course the difference in size, such as feeding, discharging, equipment power, number of blades, etc., which can meet the needs of customers with different processing volumes.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231