What is the use of electrolytic copper?

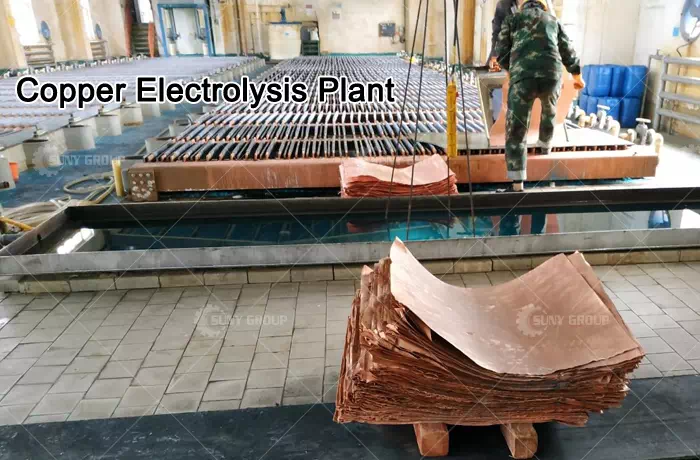

Copper electrolysis is a common industrial technique in which pure copper is separated from blister copper through an electrolytic process. The obtained pure copper with extremely high purity can be widely used in the fields of electronics, electrical appliances, construction and manufacturing, and its importance cannot be ignored.

Copper electrolysis technology principle Copper electrolysis is the process of separating copper metal by ion migration and redox reaction under the action of electric current. The technology is based on Faraday's first law, that is, by dissolving charged metal ions in an electrolyte solution, under the action of an electric current, copper ions are reduced to metallic copper at the cathode, while anions are oxidized at the anode to release electrons. In this way, pure copper metal is deposited on the cathode forming electrolytic copper.

Advantages of SUNY GROUP copper electrolysis technology equipment:

• High-purity copper production: The purity of electrolytic copper can reach more than 99.99%, much higher than other production methods. This makes electrolytic copper a key raw material needed to manufacture high-quality electronics.

• Saving energy and resources: Compared with traditional smelting methods, copper electrolysis technology can significantly reduce energy and resource consumption. It avoids energy loss during high-temperature smelting and reduces the need for limited ore resources.

• Environmentally friendly and sustainable: Copper electrolysis technology does not produce a large amount of waste gas, waste water and solid waste, and has less environmental pollution than traditional smelting methods. In addition, the production process of electrolytic copper can be recycled, which minimizes the waste of resources.

• Precise control of copper quality: In the production process of electrolytic copper, precise control of copper quality can be realized by adjusting parameters such as current density, electrolyte composition and temperature. This adjustability enables copper electrolysis technology to produce copper materials that meet specific requirements according to different needs.

• Automated production: Copper electrolysis equipment can be operated automatically, reducing labor costs and operational risks. The automatic control system can monitor and adjust the parameters in the electrolysis process to ensure the stability and consistency of production.

Copper electrolysis technology plays an important role in modern industry. SUNY GROUP has rich experience and technical equipment in copper electrolysis, especially e-waste crude copper electrolysis. Through the production of high-purity copper, it can save energy and resources, be environmentally friendly and sustainable, and precisely control the quality of copper. The demand for high-quality copper materials in the field. At present, it has provided copper electrolytic refining solutions and technical equipment support for many domestic and foreign customers. If you have relevant needs, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231