Equipment for the Recycling of Solar Panels

With the popularity of renewable energy, solar power has become an important part of the global energy mix. However, with the gradual end of the service life of solar panels, how to efficiently recycle and dispose of these end-of-life panels has become an environmental protection and resource recovery issue that cannot be ignored.

SUNY GROUP has developed professional solar panel recycling equipment that plays a crucial role in the process of solar panel recycling. This equipment can effectively improve recycling efficiency, reduce environmental impact, and maximize resource use.

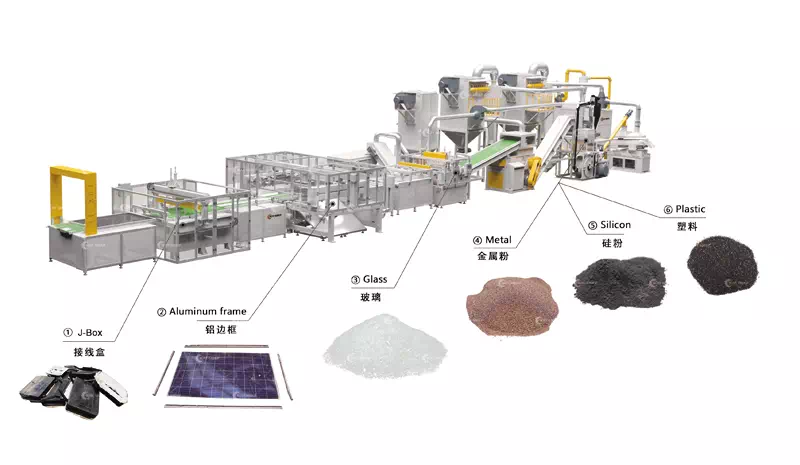

The dismantling equipment is the first step in solar panel recycling, and its main task is to dismantle the panels into recyclable basic components, such as glass panels, aluminum frames, and power boxes. The specific process includes:

Glass panel removal: separating the glass layer from the panel for cleaning and reuse or recycling.

Aluminum frame disassembly: Extraction of the aluminum frame, which can be directly recycled or reused.

Power Box Separation: recovery of the electrical components in the power box for further recycling.

This dismantling stage is crucial to the subsequent recycling process, ensuring the effective separation of different materials for subsequent processing.

The residual material from the dismantled panels then needs to be further processed by crushing equipment. The crushing equipment grinds the material into small pieces or powder, which facilitates the subsequent material sorting. The role of crushing equipment is mainly reflected in:

Efficient material size reduction for the subsequent sorting process.

Ensure the consistency of material output and improve the efficiency of sorting.

Adapt to different types of solar panel designs and structures.

Finally sorting equipment is the core equipment in the solar panel recycling process and is responsible for separating different materials such as metals, plastics, and silicon wafers. Common types of sporting equipment include:

Electrostatic Sorting Machine: separates conductive materials (e.g. metals) from other substances through electrostatic action.

Magnetic Sorting Machine: Separate ferromagnetic metals by using the principle of magnetism.

Airflow sorting machine: separates light materials (e.g. plastic film) from heavy materials by the force of airflow, depending on the weight and shape of the different substances.

Modern sorting technology is crucial for improving recycling efficiency and material purity. The use of advanced sorting technology not only significantly improves the quality of recovered materials, but also effectively reduces production costs and waste losses. Efficient sorting equipment can maximize the recovery of valuable materials and promote the recycling of resources.

Professional solar panel recycling equipment plays a crucial role in the treatment of end-of-life solar panels. Through advanced dismantling, crushing, and sorting technologies, recycling facilities can effectively extract valuable materials and maximize the recovery of resources. As technology continues to advance, solar panel recycling facilities will play an increasingly important role in improving recycling efficiency, reducing environmental impact, and promoting sustainable development. Therefore, investment in research and development of more efficient recycling equipment is critical to realizing resource recycling and promoting a green economy.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231