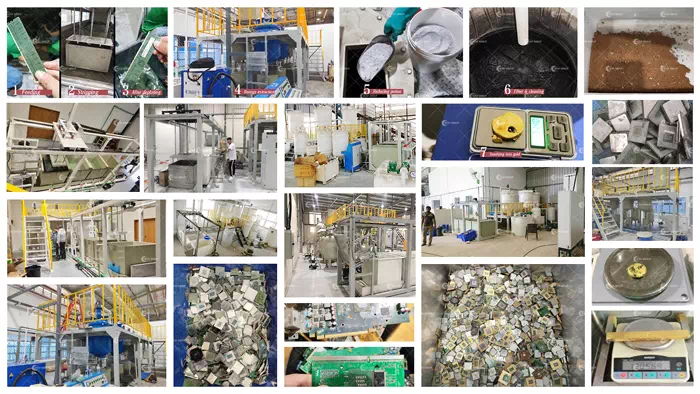

Hydrometalurgical Machine to Extract Gold from PCBs

In electronic waste (E-waste), printed circuit boards (PCBs) contain a large number of precious metals, such as gold, silver, palladium, etc., which is due to their excellent electrical conductivity, corrosion resistance, and high chemical stability. However, with the rapid replacement of electronic products, the number of discarded PCBs is increasing year by year, which contains a very high value of metal resources, especially gold, whose content is low but the economic value is considerable. Therefore, the recovery of precious metals such as gold from waste PCBs is of great economic and environmental significance, as it contributes to the recycling of resources and reduces the dependence on natural mineral resources.

Hydrometalurgical Machine to Extract Gold from PCBs

Hydrometallurgical plants have a compact structural design and usually include modules such as leaching tanks, agitation systems, filtration units, and metal recovery systems. The leaching tank is used to realize the chemical reaction, the stirring system ensures full contact between the solution and the material, the filtration unit separates the residue from the solution, and the metal recovery system is used to extract and purify the target metal. In addition, automation and control systems, such as PLC (Programmable Logic Controller) and SCADA (System for Data Acquisition and Supervisory Control), play a key role in the entire production process. These systems monitor process parameters in real-time, ensure stable equipment operation, improve recovery efficiency, and reduce manual intervention, helping to achieve efficient recovery on an industrial scale.

The workflow of the hydrometallurgical recovery process is divided into several key steps. The first is raw material pre-treatment, which includes crushing, sorting, and classifying in order to improve leaching efficiency. This is followed by the chemical leaching stage, where commonly used leaching agents, including cyanide, thiosulphate, and hydrochloric acid-hydrogen peroxide, are used to dissolve the metal ions into solution through a chemical reaction. Next, methods such as precipitation, solvent extraction, or ion exchange are used to separate the metal ions from the solution and form a precipitate. Finally, gold recovery and purification are carried out to extract high-purity metals by means of reduction or electrolysis, etc., to achieve the goal of resource reuse. Each link complements the other to ensure that the recycling process is safe and efficient and resource utilization is maximized.

Hydrometallurgical equipment is of great significance in the field of electronic waste recycling. It not only efficiently recovers the precious metal resources in waste PCBs and reduces the dependence on natural minerals, but also significantly reduces environmental pollution and realizes a green recycling mode. Meanwhile, through automated control and efficient process optimization, the hydrometallurgical recycling system has good scalability and economy, adapting to the needs of large-scale industrialized production.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231