Circuit board recycling equipment environmental protection process technology

The replacement cycle of electronic products is constantly shortening, and the number of waste electronic products is increasing day by day, which has caused serious harm to the environment. The recycling of electronic waste has become an urgent problem to be solved. Electronic waste contains many materials that can be recycled, such as various plastics that can be directly recycled; the recycling of metal and resin fiber materials should be processed and disposed of using environmentally friendly process technology and equipment for circuit board recycling equipment .

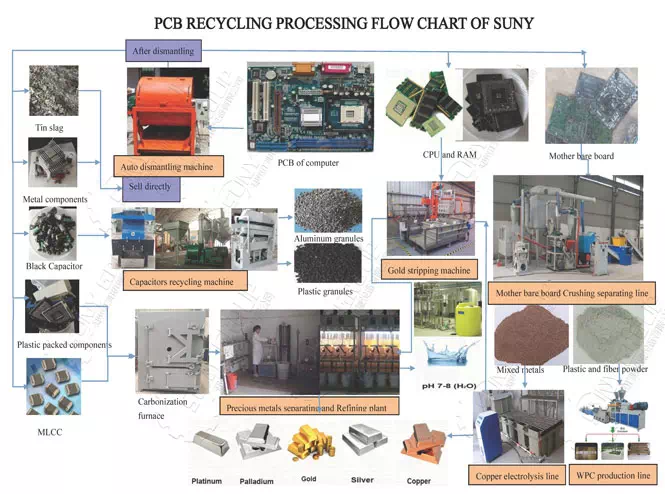

1. Dismantling: At present, the dismantling of electronic waste is generally done by hand, and mechanical equipment is used as an auxiliary, but with the rapid development of the electronic industry, the amount of electronic waste is increasing, and it is necessary to consider the use of mechanized treatment methods to improve treatment. efficiency. The device for automatic disassembly of electronic components in waste circuit boards automatically disassembles old circuit boards. The mechanical treatment method of the circuit board recycling equipment using the physical properties difference between the components for sorting has the advantages of low cost, simple operation, not easy to cause secondary pollution, and easy to achieve large-scale. The current mechanical treatment methods mainly include dismantling, crushing, sorting and so on.

2. Crushing: Circuit board recycling equipment and its circuit board crusher select effective crushing equipment according to the physical characteristics of the material, and select the crushing degree of the material according to the sorting method used, which can not only improve the crushing efficiency, reduce energy consumption, but also It can also provide prerequisites and guarantees for the effective sorting of different materials. Fully consider the physical properties of the material. For example, the waste circuit board after the removal of components is mainly composed of glass fiber reinforced resin copper clad laminate, which has the characteristics of high hardness, strong toughness, and good bending resistance. equipment is more appropriate. The shearing action is used to shred the waste printed circuit board, and the entanglement of the metal after dissociation is reduced, and a better dissociation effect is obtained.

3. Sorting: Electrostatic sorting uses the electrical difference of substances in a high-voltage electric field to achieve sorting, which is very effective for waste recycling. There are two charging mechanisms: one is to charge by ion or electron collision, such as corona cylindrical sorting machine; the other is to charge by contact and friction, such as triboelectric separation, which can sort a variety of different materials , especially for two mixed plastics, the sorting is very effective. Electrostatic separator for separating metals and plastics, can separate particles smaller than 0.1mm in size. The electrostatic separator separates waste circuit boards to recover metals. For particles of 2-0.5mm, the recovery rate is higher.

From the perspective of resource recycling utilization and environmental protection, with the rapid increase of waste printed circuit boards, recycling waste printed circuit boards has received more and more attention. SUNY GROUP environmental protection circuit board recycling equipment recycles waste printed circuit boards The technology is mature. Circuit board recycling equipment recycles waste printed circuit boards. An environmentally friendly and economically feasible mechanical and physical recycling process including dismantling, crushing, sorting and other processes has been established. Separation and recycling of non-metallic materials.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231