The Importance of a Dedicated Facility for Lithium-Ion Battery Recycling

As demand for portable electronic devices and electric vehicles continues to grow, so does the use of lithium-ion batteries. While these batteries bring convenience and power to our daily lives, their disposal poses significant environmental challenges. Recognizing the importance of sustainable waste management, establishing dedicated facilities for lithium-ion battery recycling has become critical. The purpose of this article is to highlight the importance of such facilities and to shed light on the processes and equipment involved in lithium-ion battery recycling.

Lithium-ion batteries contain recyclable precious metals such as lithium, cobalt and nickel. But at the same time, these batteries can cause soil and water contamination if not disposed of properly, so establishing dedicated recycling facilities is crucial to minimizing the environmental impact of lithium-ion batteries.

Lithium-ion battery recycling process:

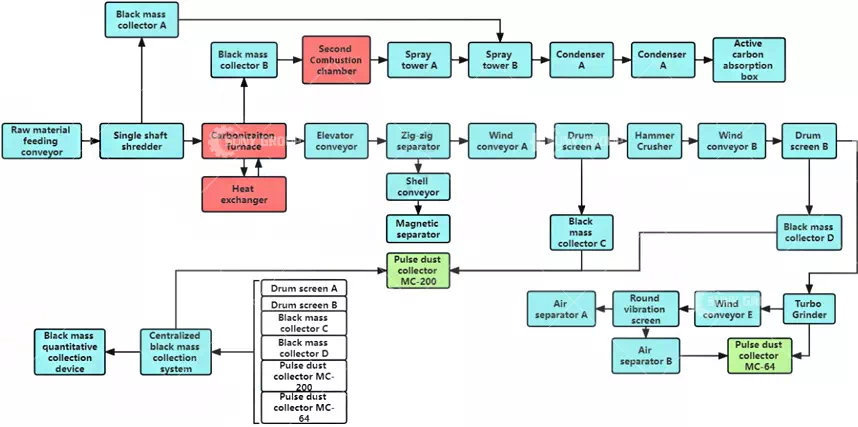

Lithium battery recycling process flow chart

The dedicated recycling facility uses a series of processes to extract valuable materials from lithium-ion batteries while ensuring the safe disposal of hazardous components. These processes typically include:

Collection and sorting: The first step involves the proper collection and sorting of used batteries. Dedicated collection points ensure that batteries are not disposed of with the regular waste stream but are sent directly to recycling facilities.

Battery Discharge: Before recycling, batteries need to be discharged to eliminate the risk of electrical hazards during disassembly and processing. Use specialized equipment to safely discharge batteries.

Battery Teardown: In this stage, the battery is disassembled to separate the different components. Manual and automated processes are used to remove casings, electrolytes and electronic components.

Crushing and sorting: After dismantling, it is shredded and ground to separate and recover valuable materials such as lithium, cobalt, nickel and other metals. Various techniques such as leaching, precipitation and solvent extraction are utilized to efficiently recover materials.

Material refining: Recycled materials undergo further refining processes to obtain high-purity metals suitable for reuse in battery production or other industries. These refining technologies include smelting, precipitation and electrochemical processes.

Equipment used in lithium-ion battery recycling facilities:

Lithium Battery Recovery Equipment

Battery Crusher: These devices are designed to crush and pulverize batteries in order to achieve efficient separation of different components.

Mechanical separator: Mechanical separators use technologies such as screening, magnetic separation, and eddy current separation to effectively separate materials based on their physical properties.

Thermal treatment unit: Some batteries require heat treatment to recover the valuable materials within them. The heat treatment device (continuous carbonization furnace) uses processes such as pyrolysis or high-temperature furnaces to perform efficient separation based on the thermal properties of the components.

Leaching Reactors: Leaching reactors are used in chemical processing processes to extract valuable metals from battery components. These reactors enable metal dissolution and further enable efficient separation.

When faced with the environmental challenges posed by lithium-ion batteries, it is particularly important to establish dedicated recycling facilities. As an industry leader, SUNY GROUP is committed to using appropriate recycling processes and specialized equipment to ensure the safe handling of hazardous materials and recover valuable resources. If you are interested in lithium battery recycling equipment, we are always at your disposal to provide consulting services. We are passionate about providing an excellent user experience and look forward to communicating with you. Please feel free to contact us and we will be happy to serve you.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231