The Latest Solar Panel Recycling Technology: Material Reuse and Profitability

With the rapid development of the solar energy industry, solar panel recycling has become a topic of great concern. As a large number of solar panels are installed and used, the need to recycle and dispose of waste solar panels is also growing. Against this background, SUNY GROUP has developed a complete set of waste solar panel recycling production lines, aiming to solve the problem of processing waste solar panels and achieve effective recycling and reuse of resources.

The latest solar panel recycling technologies and methods:

Solar Panels Recycling Process Equipment

Solar panel dismantling machine: Solar panel dismantling machine is the key equipment used to dismantle and separate solar panels. It usually includes drilling devices, stripping devices and cutting devices, etc. The drilling device is used to penetrate the backsheet of the solar panel for subsequent disassembly and separation. The stripping device is used to strip the glass and backsheet from the solar panels. Cutting units are used to cut solar panels into smaller components for material recovery and reuse.

Crusher: The crusher is used to crush solar panels that have been stripped of glass and frames to better separate the materials inside. The crusher can break the solar panels into smaller particles to facilitate the subsequent sorting and recycling process. Types of crushers include single-shaft shredders, double-shaft shredders, pulverizers, etc. Choose the appropriate crusher equipment according to the characteristics of the solar panels and recycling needs.

Vibrating screening machine: Vibrating screening machine is used to classify and sort the broken solar panel fragments. It screens and separates debris according to size through different apertures of the vibrating screen. This keeps materials of different sizes separated for subsequent material recycling and reuse.

Magnetic separation equipment: Magnetic separation equipment is used to separate magnetic materials such as iron and steel in solar panels. It uses the properties of magnetism to separate magnetic materials from non-magnetic materials in solar panels. This can effectively reduce impurities and improve the quality and recycling rate of subsequent materials.

Air flow sorting equipment: Air flow sorting equipment uses the action of air flow to separate light materials and heavy materials in solar panels. By adjusting the speed and direction of the airflow, lightweight materials such as plastic and glass can be separated from heavier materials such as metal in solar panel fragments for subsequent recycling and reuse.

Electrostatic sorting equipment: Electrostatic sorting machines separate metal, glass, plastic and other materials in solar panels by generating an electrostatic field and utilizing electrostatic attraction or repulsion between materials for subsequent recycling and reuse.

Business models and profit opportunities in the solar panel recycling industry:

Key players in the solar panel recycling industry include specialist recycling companies and reprocessing plants. They play an important role in different stages of solar panel recycling and participate in the industry through different operating models and profit opportunities.

Professional recycling company:

Professional recycling companies specialize in recycling discarded solar panels from the market. They usually have the following operating models and profit opportunities:

Recycling network: Professional recycling companies have established recycling networks, including establishing cooperative relationships with solar panel installers, power stations and individual users to collect waste solar panels. The scrapped solar panels will be sent to a reprocessing plant for subsequent processing.

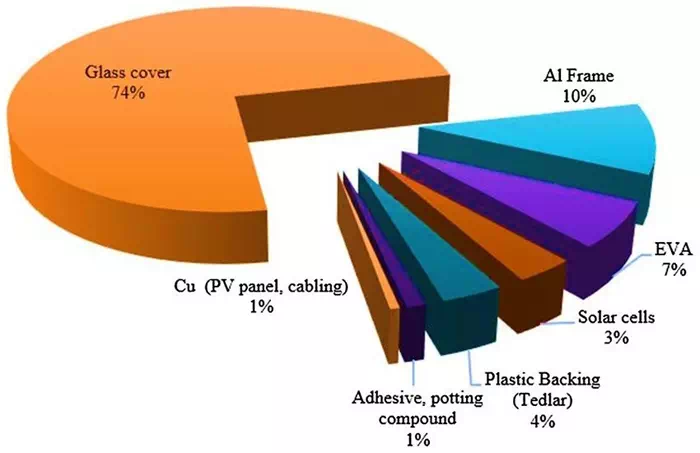

Solar Panel Composition

Reprocessing plant:

Reprocessing plants are responsible for processing and reusing discarded solar panels. Their operating models and profit opportunities include:

Material separation and crushing: Reprocessing plants use machinery to dismantle, separate and crush waste solar panels so that the different materials can be recycled and processed.

Material recycling and reprocessing: Reprocessing plants recycle valuable materials from solar panels, such as silicon wafers, aluminum frames, silver wires, etc. These materials can be reprocessed to make new solar modules or other products.

The solar panel recycling technology developed by SUNY GROUP provides a feasible solution for the disposal of discarded solar panels and achieves effective recycling and reuse of resources. Through the latest recycling technology and equipment, waste solar panels can be efficiently dismantled, separated and recycled, and the valuable materials can be used by reprocessing plants to manufacture new solar modules or other products. This not only helps reduce resource waste and environmental pollution, but also creates new business opportunities and profit models for the solar industry. If you have any needs or want to know more information, you can contact us at any time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231