Machine for Recycling Old Solar Panels

The recycling and processing equipment for waste solar photovoltaic panels uses physical crushing and sorting technology to extract silicon powder, copper powder and plastics with high market value inside. The recycling of photovoltaic modules usually includes three main links:

End-of-life solar panels to be recycled

First, the components are disassembled by machine or manually to remove the back panel, wires and aluminum frame;

Secondly, crush the components to remove the tempered glass;

Finally, the remaining panels are crushed and sorted to extract metal and plastic.

Photovoltaic modules are mainly composed of aluminum frames, glass, cells, EVA film and backsheets. The main component of glass is silica, with minor components including soda ash, limestone, magnesium oxide, alumina, mirabilite and carbon. EVA film is mainly composed of ethylene-vinyl acetate copolymer. The core components of the cell are monocrystalline silicon and polycrystalline silicon. The frame is mainly made of metallic aluminum, while the back panel is composed of two layers of PVF film and one layer of PET film. More than 90% of these materials can be recycled again.

This equipment is used to process various waste solar photovoltaic panels and photovoltaic modules to recover metals for reuse. It can recycle up to 95% of the material in crystalline silicon photovoltaic panels and specializes in processing end-of-life crystalline silicon photovoltaic panels. A typical crystalline silicon solar panel is composed of 65-75% glass, 10-15% aluminum frame, 10% plastic and 3-5% silicon. The photovoltaic panel recycling and processing equipment we produce can dismantle, sort, process and recycle 98% of the materials.

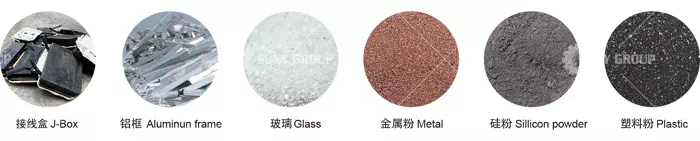

Scrapped solar panels are recycled to obtain J-Box, Aluminun frame, Glass, Metal, Sillicon powder, Plastic etc.

After sorting and processing, the materials are sent to different industries for reuse. Two-thirds of the glass will be recycled into cullet for use in glass manufacturing; aluminum frames will be sent to aluminum refineries; waste plastics can be used as fuel in cement plants; and the recycled silicon can be used in the precious metals industry reused; remaining wires and connectors will be crushed and sold as copper beads.

The processing process is as follows: First, the waste photovoltaic panels enter the shredder for shredding, and then enter the crusher for crushing, breaking up the EVA film and single crystal silicon wafers. The broken materials enter the collector through the induced draft fan, and then go through the sorting process to separate the silicon. The remaining mixed materials enter the crusher, and then enter the air flow sorting screen through the air closer, using air flow and vibration to collect valuable metals and plastics, and at the same time collect the dust generated by the air flow sorter.

The characteristics of this equipment include: using crushing and sorting technology to realize the reuse of solar panels; compact structure, reasonable layout, stable performance, and low noise; waste photovoltaic panel recycling and processing equipment adopts PLC control, and the entire production line realizes automated operation; the equipment has high Efficiency and high recovery rate can fully utilize the resource value of waste solar photovoltaic panels.

The above is the working principle and process of a common waste solar photovoltaic panel recycling and processing equipment developed by SUNY GROUP. The actual equipment and processing process may be different. The specific plan and equipment configuration can be adjusted and optimized according to the actual situation. . We have a rich technical team and manufacturing experience and are an industry leader in solar panel recycling. If you have needs or have related questions, you can contact us at any time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231