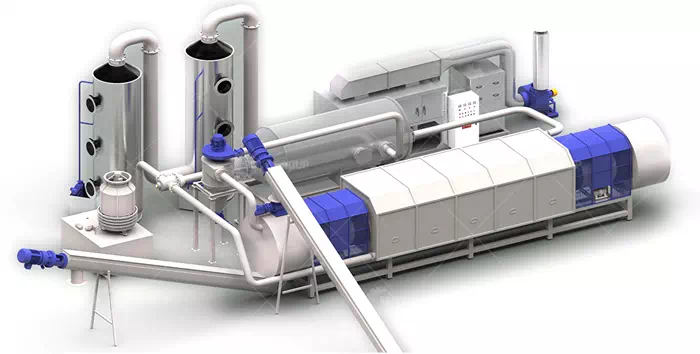

UBC cans painting removing recycling production line

The UBC (Used Beverage Can) recycling production line is a production facility that specializes in processing waste cans. Its goal is to recycle the aluminum material in the cans. The process flow of the can paint removal and recycling production line mainly includes shredding, paint removal, smelting and purification. This article explains these steps in detail and the equipment used in each step.

UBC before and after paint removal

1. To shred

The first step is to shred the collected UBC cans. This step is usually done using a powerful shredder. The working principle of the shredder is to tear cans into small pieces through rotating blades. This process greatly reduces the volume of the can, making it easier for subsequent processing.

2. Remove paint

Paint removal is an important part of recycling cans. Cans are coated with an anti-corrosion paint during the production process, which needs to be removed during the recycling process. This step is usually done using a carbonization furnace. The carbonization furnace is a high-temperature device that can pyrolyze the paint inside the can in an oxygen-free environment, decomposing it into gaseous and solid residues. The gaseous substances produced by decomposition can be purified by exhaust gas treatment equipment.

Carbonization Paint Removing Furnace

3. Smelting

The paint-removed cans need to be melted to further separate aluminum and other impurities. This step is usually accomplished using a smelting furnace. The smelting furnace heats the can to a high enough temperature that it melts into a liquid state. During this process, aluminum will settle at the bottom, while other light impurities such as plastics, paper, etc. will float to the surface and can be removed.

4. Purification

The final step is purification, where the goal is to extract pure aluminum. The purification process is usually accomplished using electrolysis equipment. Electrolysis equipment can use electric current to separate liquid aluminum from other impurities to obtain pure aluminum.

Overall, the UBC can paint removal and recycling production line is a complex but efficient system that converts discarded cans into reusable aluminum materials. Operation of this system requires a range of specialized equipment, including shredders, carbonization furnaces, smelting furnaces and electrolysis equipment. These devices work together to make can recycling efficient and environmentally friendly. SUNY GROUP is a professional manufacturer of solid waste recycling equipment. It has rich experience and complete after-sales services in UBC recycling and reuse. It also has mature solutions in e-waste recycling and lithium battery recycling. If If you have any needs, please feel free to contact us at any time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231