Measures to Solve the Overheating of Bearings in Large Metal Crusher Equipment

Large-scale metal shredder equipment is a machine for smashing scrap metal materials, such as common scrapped cars, cans, paint buckets, moon cake boxes, etc. All metals can be smashed, and it has become an indispensable one for recycling large pieces of scrap metal. equipment. At the same time, as large-scale metal crusher equipment is more and more widely used, there will inevitably be large or small problems in the process of use. Although these small problems will not affect much, but for our production efficiency and Personal safety, so we always have to address that. Because a little mistake in small details may eventually lead to a major accident, we must prevent minor problems and solve these small problems fundamentally.

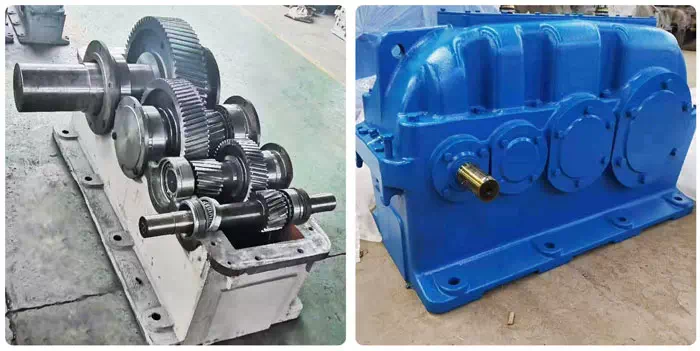

Bearing structure of double shaft shredder

Today, let’s talk about the solutions when facing the overheating of the bearings of large metal shredder equipment. When putting into processing and production, special attention should be paid to the temperature of the internal bearing of the metal shredder equipment. If there is an accident, it must be carried out immediately. After all, the bearing is the core component of the whole set of equipment. If it fails, it will directly affect the operation and production efficiency of the equipment.

First of all, friends who know the equipment know that the production of the equipment requires a balance. The two bearing seats are uneven, or the rotor of the motor and the rotor of the shredder are not concentric, which will cause the bearing to be impacted by additional loads. It will cause the bearing to overheat. If this happens, immediately stop the inspection to avoid bearing damage. In addition, the fit between the bearing cap and the shaft of the metal crusher equipment is too tight, and the fit between the bearing and the shaft is too tight or too loose, which will cause the bearing to overheat. Once this problem occurs, friction noise and obvious vibration will be emitted during the operation of the equipment. In this case, we should stop the machine to remove the bearing, repair the friction parts, and then reassemble as required. Too much or too little lubricating oil in the bearing is also part of the reason for the bearing overheating. Therefore, it is necessary to add lubricating oil on time and quantitatively according to the requirements of the equipment manual to prolong the service life of the bearing of the metal crusher equipment.

I believe that the above introduction has provided solutions for your next problem. The above information is provided by SUNY GROUP. As a professional metal crusher manufacturer, it can not only provide scientific and effective solutions for customer needs, but also It can provide customers with high-quality after-sales service and solve various problems that may be encountered in the later use process. If you have more questions, please feel free to contact us.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231