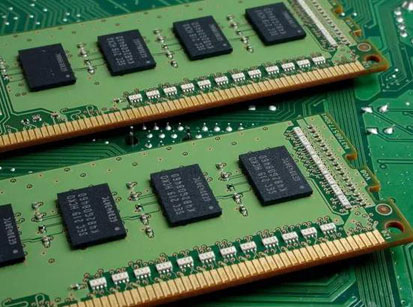

PCB Circuit Board Precious Metal Extraction Recycling Line

As we all know, PCB boards, circuit boards, circuit boards, and PCB products are the basic components of electronic products, and all electronic components must be soldered on them. The circuit boards contain some precious metals such as gold, silver, platinum, palladium, rhodium , copper, etc. After we recycle PCB boards, circuit boards, and circuit boards, how do we deal with the precious metals in them?

First of all, when the circuit boards are recycled, they need to be sorted first, because even if they are called circuit boards, some are gold-plated, and the outer layer of the circuit board will be more expensive, and some are not gold-plated, and the outside is a white tin-plated layer , these are cheap. Gold plating is also divided into two types, namely water plating and electroplating. Among them, water plating gold is relatively thin, and its value is not as high as that of electroplating gold. Therefore, when we do the recycling of circuit boards, we will also evaluate the value of circuit boards according to the method and content of gold plating. Gold-containing and non-gold ones need to be opened separately.

The second is to carry out precious metal refining, extraction and recycling of waste PCBs:

1. Physical and mechanical crushing and sorting

According to the different physical properties of the PCB, it is recycled by physical and mechanical means. Mechanically break the PCB, disintegrate and separate its metal and organic matter, and improve the sorting efficiency. When the crushed particles reach 0.6mm, the metal can basically achieve 100% dissociation, but the choice of crushing method and series depends on the subsequent process. The crushed materials, according to their differences in physical properties such as density, particle size, electrical conductivity, magnetic permeability and surface characteristics, can be processed by wind shaker technology, flotation separation technology, cyclone separation technology, floating-sink separation and eddy current separation technology. sorting.

2. Hydrometallurgy (precious metal refining and extraction)

Hydrometallurgical technology, placing PCBs in acids such as nitric acid, sulfuric acid and aqua regia to remove metals from electronic waste and then recycle them. It is currently the most widely used method for dealing with electronic waste. Compared with pyrometallurgy, hydrometallurgy has the advantages of less exhaust gas emission, easy disposal of residues after metal extraction, significant economic benefits, and simple process flow.

(a) Analyze the material containing the precious metal to be extracted, and determine the content of the precious metal in the material.

(b) alloying the material containing the precious metal to be extracted with a known amount of a base metal (eg, copper) to form an alloy with a known concentration of the precious metal to be extracted

(c) Dissolving the base metal in the acid, leaving the refined precious metal, and filtering the precious metal from the resulting solution.

Electronic waste (PCB) has complex and diverse characteristics, and it is difficult to recover completely by a single recycling technology. The electronic waste treatment technology needs to be continuously optimized to maximize resource recovery, and the treatment technology should be scientific and industrialized. In short, the treatment and recycling of waste PCBs can not only protect the environment, prevent pollution, but also facilitate the recycling of resources and promote sustainable social and economic development. SUNY GROUP has rich experience and advanced technical equipment in e-waste recycling, and has a complete set of solutions for e-waste recycling. If you are interested, please contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231