PVC copper wire recycling machine

The waste PVC copper wire crushing and peeling separator is specially used for recycling metal resources and plastic skins in waste cables, as well as a small amount of brass. The equipment is easy to operate, occupies a small area, and is convenient to move and operate.

The main components of electric wires and control wires are PVC sheath and copper core, and some wires are mixed with copper, aluminum, lead and other metals. Only by separating the outer skin of the wire from the inner metal can it have the value of recycling and reuse. However, because these control lines are uneven in thickness and disorderly, it is more difficult to separate the inner and outer materials. Some small recycling companies will incinerate the outer layer of PVC to get the inner copper wire, but this method not only pollutes the environment, but also wastes PVC plastic.

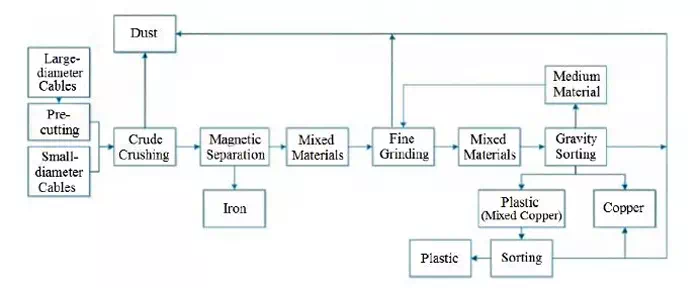

PVC copper wire recycling flow chart

At present, the cost-effective and non-polluting method is to use waste PVC copper wire crushing and peeling separator to separate various wires and crush them, and then separate PVC particles from copper-based metal particles. The whole process will not change the performance of the material, nor will it cause secondary pollution. Even if impurities, polymers and ferrous metals are removed from the pellets, it still contains small amounts of lead, brass or aluminum, and these impurities are typically as high as 3%. If the purity of copper particles is increased to 99.9%, the material value will increase by 30%. Therefore, it is very important to further remove impurities from copper rice. Copper recovered from copper cables is a valuable metal resource. But recycled copper often contains cable sheath, iron metal, and small amounts of lead, brass or aluminum, often at levels as high as 3 percent. If the purity of copper particles is increased to 99.9% using electrostatic separation technology, the value of the material will increase by 30%.

Waste PVC copper wire crushing and peeling separator generally includes crushing and separation, sorting, dust collection, magnetic separation and other systems, and crushing and separation usually includes crushers, pulverizers and other auxiliary equipment. Magnetic separation facilities are usually installed after the crusher and pulverizer. Since the iron materials obtained after magnetic separation contain some undetached plastics and copper, a set of degumming machines can be installed to realize the separation of iron materials from plastics and copper. for the purpose of removal.

Sorting: including separation equipment, specific gravity separation equipment and other auxiliary equipment. Separation equipment mainly separates miscellaneous materials produced by crushing. The specific gravity separation equipment mainly separates copper and other precious metals and plastics through gravity separation.

Dust collection: Including cyclone dust collector, bag dust collection system, all crushers, pulverizers, separation equipment, specific gravity separation equipment and other equipment that may generate dust should be equipped with a dust collection system. The exhaust gas is discharged uniformly after dust collection,

Magnetic separation: After the crusher, a magnetic separator is installed after the crusher to remove iron, increase copper purity and protect knives.

Waste wire and cable resource recovery equipment adopts mechanical and physical methods to recover metals and non-metals in waste wires and cables through crushing and sorting processes for a large number of mixed wires and cables produced by scrapped household appliances and scrapped cars. Waste PVC copper wire crushing and peeling separator is to effectively recycle and reuse all kinds of waste miscellaneous wires and scrapped cables contained in dismantled waste electrical and electronic products, and separate metal (copper) and non-metal (plastic skin) Effective separation has always been the dismantling equipment for waste electrical and electronic products.

The PVC copper wire recycling machine developed and manufactured by SUNY GROUP has a complete range of models, suitable for processing industrial cables, communication cables, etc., and has a high degree of automation. The equipment is integrated with a small footprint and is easy to move and operate.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231