Paper-plastic separator maintenance

The paper-plastic separator can separate the pulp and plastic on the plastic-coated materials such as milk cartons, wrapping paper, coated paper, paper cups, PP bags, etc. without heating or chemical liquid, and the water can be recycled. , Improve the utilization value. Because of the good separation effect, the separated pulp and plastic are very clean, plastic can be granulated, and paper can be made into pulp, both of which can realize new value. It is the first equipment for making plastic granules and paper pulp. In the process of using the paper-plastic separator, we must especially do a good job in related maintenance and maintenance work, so that the equipment can maximize its value.

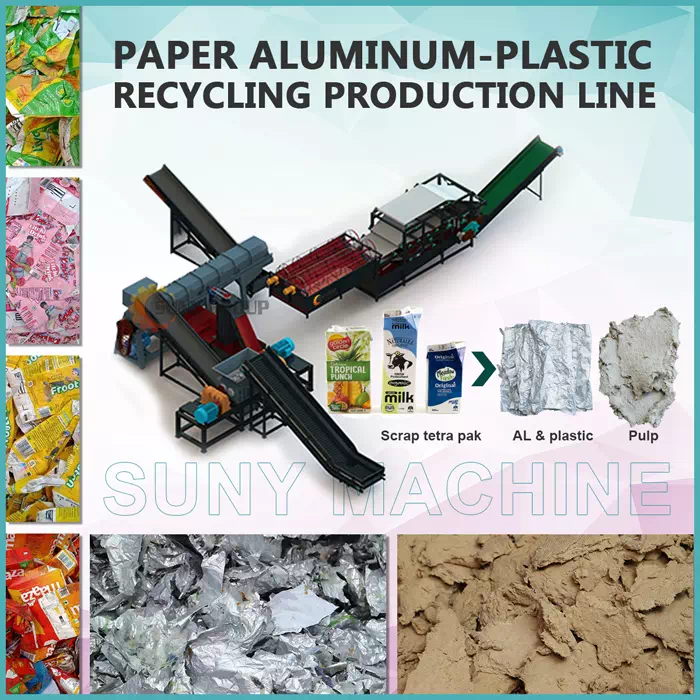

Paper-plastic separation and recycling production line

The maintenance and maintenance of the paper-plastic separator mainly include the following aspects:

1. Close the slag discharge valve, fill the tank with clean water to 1/3 height, and check whether there is any leakage in the slurry system pipeline. Start the motor, check whether the direction of rotation of the impeller is correct, and pay attention to whether the equipment is running normally. When the equipment is operating normally, it can be fed. Feeding is based on the principle of uniformity, and the concentration is properly controlled.

2. The themes of contemporary new paper-plastic separators all adopt national standard products, that is, GB products. Compared with the products on the market, the material thickness and quality have far superior advantages. Specifically, we can look at the following:

1. The barrel body of the paper-plastic separator is made of cold-bent 8mm-12mmGB steel plate, which is better in corrosion resistance.

2. The conical wall is the main force-bearing friction surface, and it adopts a thicker design and a thicker manufacturing process of 10mm-12mm.

3. The frame of the paper-plastic separator adopts double-sided welding technology, even multiple times of welding, to ensure firmness and reliability.

4. The split bearing body is a casting. Ductile iron is a component used in standard machinery at present. It has good weldability and machinability, and has high impact toughness at room temperature. Moreover, the plasticity is high, the brittle transition temperature is low, and the low temperature toughness is also good. Used as parts that can withstand dynamic and static loads such as high shock vibration and torsion, require high toughness and plasticity, especially parts that require a certain impact value at low temperature.

5. The separating cutter head of the paper-plastic separator is made of giant steel blades made of GB manganese steel, and the wear resistance is several times that of ordinary steel.

From the above points alone, we can see the market advantages of the contemporary new paper-plastic separator. In this era of increasing emphasis on resource recycling, the paper-plastic separator has a great responsibility. If you want to know more about the paper-plastic separator, please feel free to contact us by leaving a message.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231