Precious metal recovery process from e-waste

With the rapid development of the electronics industry, the consumption of precious metals as one of the raw materials for production is increasing. Scientific, reasonable and efficient recycling of precious metals in electronic waste can not only save resources and energy, but also achieve the purpose of protecting the environment. Here, the recovery and treatment technology of precious metals in electronic waste is expounded, the basic principles and research progress of various technologies are introduced, and the precious metal recovery process that has been applied in industrial production is briefly introduced.

Electronic waste, also known as electronic waste, includes various household appliances such as computers, communication equipment, televisions, refrigerators, washing machines and other household appliances discarded after use in daily life, as well as electronic instruments and meters eliminated in the production and office processes of enterprises and institutions. , the number is quite large.

Precious metals generally refer to 8 metals including gold (Au), silver (Ag), platinum (Pt), osmium (Os), iridium (Tr), ruthenium (Ru), rhodium (Rh) and palladium (Pd), which are expensive , resources are scarce. Due to their excellent electrical conductivity, flexibility and high strength, precious metals and their alloys are widely used in assembled circuit boards, capacitors and other electronic components in common electrical appliances such as televisions, computers and mobile phones.

With the acceleration of the replacement of electronic products and the increasing number of electronic wastes, a large number of electronic wastes containing precious metals have not been effectively recycled, which not only wastes a lot of valuable resources, but also seriously pollutes the environment. Therefore, scientific and rational recycling of precious metals in electronic waste can not only save resources, reduce production costs, but also effectively reduce waste discharge and achieve the purpose of protecting the environment.

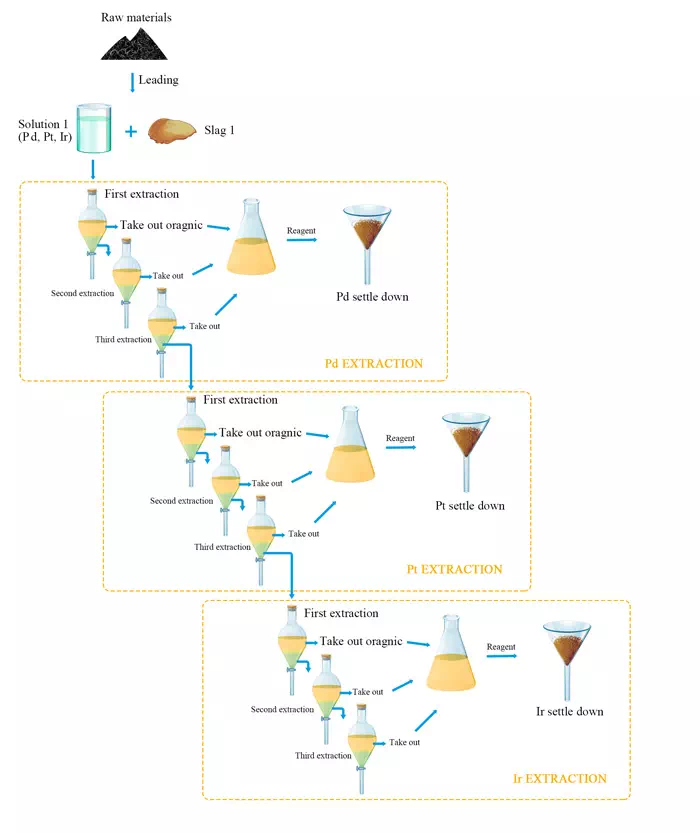

Process flow of precious metal recovery from electronic waste

The first is the dismantling of electronic waste, which usually has two purposes: (1) dismantle valuable components or auxiliary equipment, and reuse them after passing the inspection; (2) dismantle components or auxiliary equipment containing harmful substances and dispose of them separately. Traditional dismantling operations are generally done by hand, with mechanical assistance where possible. In recent years, the mechanical and automatic dismantling technology of electronic waste has become a hot spot in the research and development of dismantling.

The second is fragmentation, which is the process of breaking and breaking the object by destroying the cohesion and intermolecular force inside the object through the action of external force such as manpower or machinery. Fragmentation is a key step to dissociate the substances to be recovered from electronic waste, and the sufficient dissociation of monomers is a prerequisite for efficient mechanical sorting. Therefore, selecting effective crushing equipment according to the physical characteristics of different materials in electronic waste, and selecting the crushing degree of materials according to the sorting method used can not only improve crushing efficiency, reduce energy consumption, but also provide effective separation of different materials. Option to provide prerequisites and warranties.

At present, the equipment used for mechanical crushing of electronic waste mainly includes hammer crusher, shear crusher, rotary crusher and hammer mill crusher.

The last is sorting, the process of separating different components in electronic waste crushed products according to different physical or physicochemical properties (such as particle shape, density, etc.), usually divided into dry sorting and wet sorting 2 kinds.

Dry separation includes dry screening, pneumatic shaker or pneumatic eddy current separation, magnetic separation, electrostatic separation and eddy current separation; wet separation mainly includes hydraulic eddy current separation, flotation, hydraulic shaker, etc. Dry separation has low cost and no pollution, but currently it can only handle coarse particles, and the separation efficiency of fine particles is low. The wet separation has a high recovery rate, and the separation efficiency of fine particles is better than that of the dry separation, but the cost is higher and secondary pollution is easy to occur.

Extraction and recycling of precious metals is an important part of electronic waste recycling. As a professional electronic waste recycling equipment manufacturer, SUNY GROUP has rich experience and perfect technical equipment, from recycling and dismantling of electronic waste, crushing and sorting, to There are mature solutions for the refining and extraction of precious metals. If you are interested in e-waste recycling, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231