Scrap Solar Panel Recycling Production Line

According to the estimates of the International Energy Agency, in 2050, there will be about 4.3 billion waste photovoltaic modules in the world that need to be processed, among which glass, aluminum, silicon, silver, indium and other materials can be recycled, and the annual recycling market value is expected to reach 15 billion. Dollar.

Recycling of decommissioned photovoltaic modules not only has considerable economic benefits, but also has significant social and ecological benefits. At present, extensive, high-pollution, and high-energy-consuming photovoltaic module recycling technologies still dominate the market. While the existing dismantling process consumes a lot of energy, it also causes environmental pollution such as waste water, gas, and liquid discharge, which has a negative impact on the ecological system and environment of the dismantling site. Residents' health poses a serious threat. At present, for the recycling of solar panels, the recycling of photovoltaic modules and the formulation of standards are still lacking. The recycling industry has deficiencies such as no standards to follow, incomplete management, and a lack of recycling evaluation system. There is an urgent need for new, environmentally friendly, and energy-saving recycling technologies.

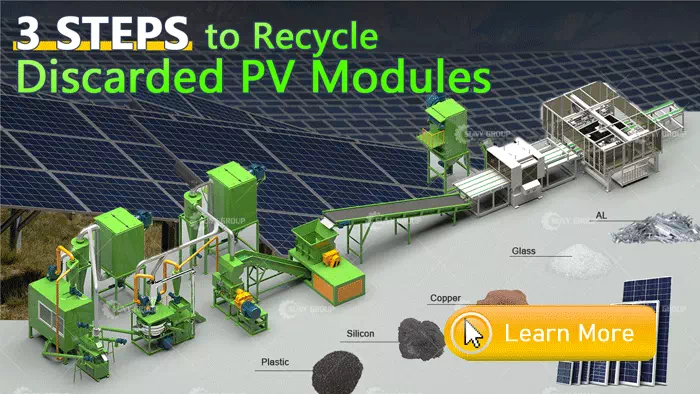

After years of research and development, SUNY GROUP has rich experience in solar panel recycling and complete technical equipment. From the dismantling of scrap solar panels, glass removal to crushing and sorting to obtain precious metals, the entire process can achieve fully automated production, and can be produced according to customer requirements. Demand customization, while related technologies are constantly updated and iterated to meet the needs of more customers.

Product performance advantages:

1. Low-cost green dismantling technology of decommissioned photovoltaic modules: Based on dismantling and crushing technology, low-cost green dismantling and separation technology of photovoltaic modules has been obtained, which has the advantages of high recovery efficiency, high purity, and low energy consumption.

2. Complete set of resource recovery and harmless treatment technology: Optimized the design of the environmental protection recycling technology route of photovoltaic modules and the harmless treatment process conditions, and formed a complete set of resource recovery technology of pretreatment-dismantling-sorting-enrichment-recycling system.

3. It includes the whole process of dismantling, crushing and screening, and the finished products include junction box, aluminum frame, glass, copper, silver, silicon and plastic.

SUNY GROUP's solar panel recycling production line is based on the advantages of physical technology, environmental protection recycling technology and selective crushing of photovoltaic modules, which can effectively crush and dissociate components (glass, silicon powder, valuable metals and polymer materials) , providing a crushing recycling method for solar panels with laminated structures. The whole treatment process does not use chemical reagents, no waste water, waste liquid and dust are generated; the crushing and separation process takes place in a sealable space, which realizes the harmless treatment process and high recovery yield and quality of each component, breaking through the original The recovery method is a technology with high energy consumption and high pollution. This project provides a large-scale, low-energy, and low-cost photovoltaic module recycling technology, which has social, livelihood and economic benefits for the recycling of solid waste and the creation of a photovoltaic green industrial chain.

If you are interested in non-recycling of waste solar energy, or if you need it, please feel free to contact us for consultation.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231