The latest recycling technology and equipment for scrap lithium batteries

Lithium-ion batteries (LIBs) are already the preferred choice for energy storage in modern portable consumer electronics such as laptops, smartphones or tablets. Moreover, as the most attractive battery technology for pure electric and hybrid vehicles, LIB is also widely used in private and industrial applications. Therefore, in view of the widespread use of Li-ion batteries, there is a need to recover and reuse their components. In addition, spent Li-ion batteries typically contain 5–20% cobalt (Co), 5–10% nickel (Ni), 5–7% lithium (Li), 5–10% other metals (copper (Cu), aluminum ( Al), iron (Fe), etc.), considering the economic value of high nickel, copper or cobalt content, it is also very necessary to carry out the recovery of lithium ion battery components.

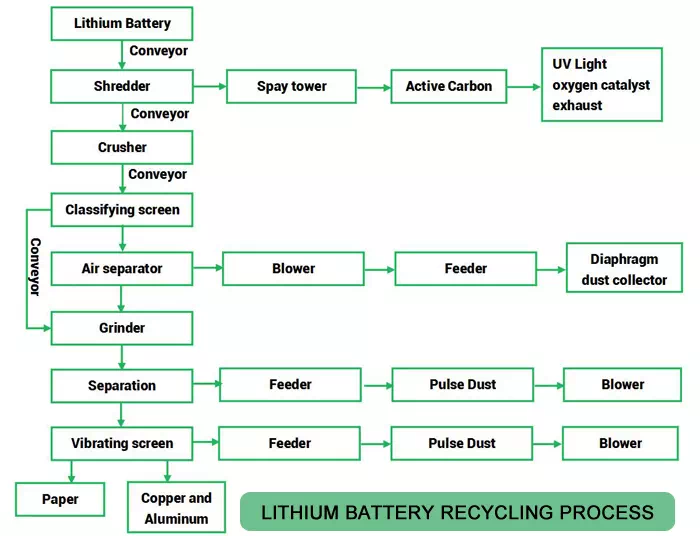

Lithium-ion battery module recycling includes two main processes: battery module discharge and disassembly. The battery is discharged before manual removal, primarily to ensure personnel safety and eliminate the risk of electric shock. Battery disassembly mainly involves disconnecting major components such as cables, battery cells, frames, electronics, etc. Usually during battery disassembly, thermal pretreatment methods are applied to safely deactivate the flammable components of the battery's electrolyte.

After the battery is disassembled, mechanical pretreatment is first required. Mechanical pretreatment is used to break down the battery and separate specific components into several streams, the main scope is to separate the metal particles (casing, copper and aluminum foil) and to concentrate the black matter, which is a mixture of positive and negative active materials and is the most valuable battery components. Therefore, mechanical pretreatment is primarily aimed at achieving maximum recovery and separation. Followed by mechanical treatment, mechanical treatment includes crushing, screening, magnetic separation, crushing, grading and other processes.

Lithium-ion battery recycling is an emerging field that could undergo major changes as processes are updated. SUNY GROUP is a manufacturer of lithium battery recycling equipment with more than ten years of experience. It is also constantly improving lithium battery recycling technology and equipment, and can customize lithium battery recycling production lines according to customer needs. At present, this equipment has been accepted by customers. Widely recognized by the company, we have many cooperative customers in Europe, America, Asia and other places. If you plan to develop lithium battery recycling business or are interested in this equipment, you can contact us at any time to give you detailed guidance and equipment information.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231