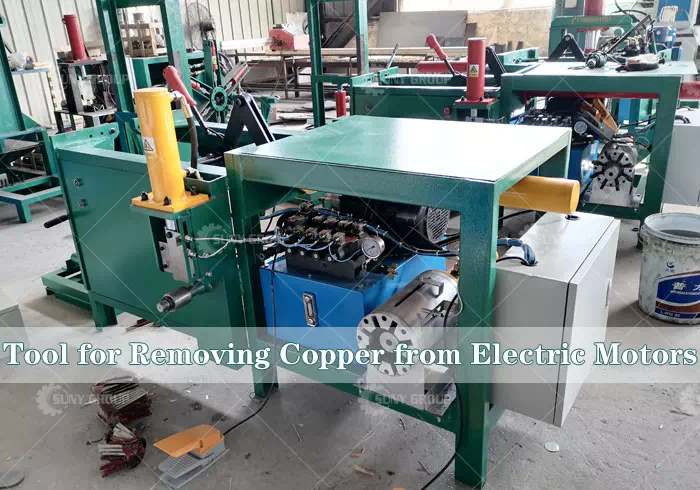

Tool for Removing Copper from Electric Motors

Tool for Removing Copper from Electric Motors - Stator Stator Rotor Cutting Machine The motor stator consists of three parts: the base, the cylindrical core mounted in the base and the copper wire wound in it. The scrap motor stator cutting and separating machine is a special machine for dismantling motor stators. The device is used in combination with a hydraulic system. The machine splits the stator base (cast iron base only) and the cylindrical iron core in two and winds the copper wire in a circle. The cylindrical iron core is pulled out to complete the dismantling process of the motor stator.

The motor stator consists of three parts: the base, the cylindrical core mounted in the base and the copper wire wound in it. The scrap motor stator cutting and separating machine is a special machine for dismantling motor stators. The device is used in combination with a hydraulic system. The machine splits the stator base (cast iron base only) and the cylindrical iron core in two and winds the copper wire in a circle. The cylindrical iron core is pulled out to complete the dismantling process of the motor stator. The machine is stable and reliable, highly efficient, easy to operate and flexible, with zero environmental pollution. It is the ideal equipment for dismantling the stator of a motor.

Working principle of the scrap stator rotor cutter:

The scrap motor stator cutting and separating machine works with a hydraulic system, using the main oil cylinder to move up and down. By changing different work stations, the motor stator seat (limited to cast iron seat) and the stator cylindrical core can be broken into two halves respectively. Another station can pull out the copper wire winding in the cylindrical core of the stator and separate the cast iron, silicon steel and copper core wire in the motor stator to complete the dismantling process of the motor stator.

Installation and commissioning:

The scrap motor stator cutting and separating machine is supplied in complete sets after assembly and commissioning by the manufacturer. Therefore, after installation, it should be carefully inspected to detect any possible undesirable problems during transportation.

1, there are no specific installation requirements for the equipment, it should only be placed on a flat surface of corresponding hardness.

2、After placing the equipment, it should be stable and should not be shaken.

3、Configure the power cord and control switch according to the power of the equipment, and access the appropriate grid according to the motor requirements.

4、Inject 46# clean hydraulic oil into the oil tank, and the hydraulic oil level should reach the height of the oil mark.

5、Debug the hydraulic station output oil pressure, control at 5-8Mpa.

6、Equipment fasteners should be solid and reliable, no loose phenomenon. Confirm that there are no obstacles in the movement area such as oil cylinders before the work test.

Through the scrap motor dismantling tool, we can easily dismantle the copper inside the scrap motor completely, compared to the manual dismantling method, more efficient, stable, and the machine, cost-effective, has significant advantages in the motor dismantling. If you want to know more information including the price, please contact us in time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231