How do you refine gold from scrap circuit boards?

If you've ever opened an electronic device such as a radio, television or even an old mobile phone, you've seen the construction inside. Have you noticed the shiny golden parts on the circuit boards? Those shiny things are actually gold. Gold is often used in circuit boards because it conducts electricity well and will not corrode or rust over time. Waste circuit boards are not "waste", 90% of which can be recycled, and even have a high value, it is "precious" almost.

It is understood that in these circuit boards, in addition to containing 30% of inert oxide and 30% of plastic, but also contains 40% of the metal material, and in these metal material, containing 0.1% of the amount of gold. And how exactly is the gold in these waste circuit boards extracted?

This is a very simple and easy to use metal separation device, which can easily separate the metal from the non-metal material in the circuit board and then refine the gold through a series of steps. Let's take a closer look at the process. Firstly, we have to distinguish between used circuit boards, which are generally divided into two categories for recycling: one is circuit boards with electronic components, which require us to dismantle the electronic components on top of the board one by one through a dismantling machine, and then proceed to the next step of dismantling down the electronic components and mastering. The second category is the circuit board without electronic components, which can be directly crushed and recycled, and then the resin, fibres, gold, silver, copper and other substances contained in it will be separated, so that we will get a good metal substance, at which point we can recycle the metal and sell it for a good price and make a profit from it.

It can be said that simple dismantling in the first category, and crushing and separation in the second, can be sold for a good price, but of course the most profitable is the complete refining of gold. To refine gold, it is important to understand the application of gold in circuit boards. Gold is widely used in the manufacture of circuit boards because of its corrosion resistance, non-embrittlement, good power supply characteristics, good reliability and strong plasticity, which can not only improve the life of the product, but also significantly reduce the failure of electronic equipment. But we also know that the price of gold is expensive, manufacturers can not use gold to make all the parts, but with copper, zinc, tin to replace the use of gold part, only like circuit boards, integrated chips CPU, computer memory sticks, heat pipe cooling board and other key components must use gold, will choose to use gold, especially some good electronic equipment, the use of gold will be greatly increased It is also said that the better the electronic equipment, the higher the gold content in it will be. For example: some laptop PCB circuit boards will contain 0.2 grams of gold, a small piece of the CPU will also contain 0.5 grams of gold, we hear here do not rush to open their computer to take a look, and so scrapped to open the study is not too late. In the PCB circuit boards of mobile phones, computer memory sticks, resistors, capacitors, these parts have gold made plating, which contains a high gold content when the integrated IC of the central air conditioning.

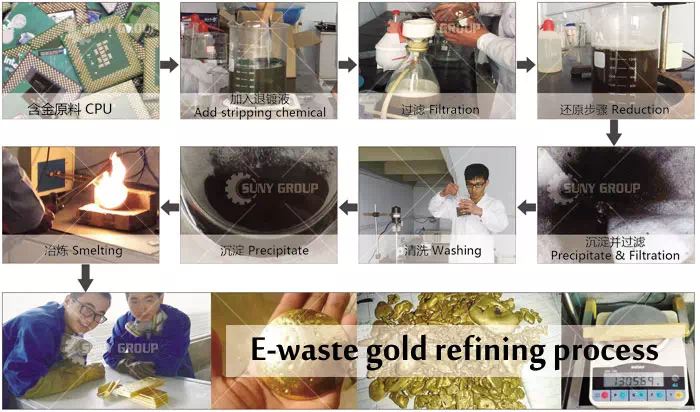

So how do you refine the gold? In general, the refining of gold is divided into three steps: one is a high-temperature furnace calcination, the role of this step is to calcine the circuit board through high temperature capacitors, resistors, and some residues to solve; two is through the use of some chemical agents for dissolution, such as sulfuric acid, etc.; three is to continue to heat up the melting furnace inside the material, to ensure that the temperature reaches 1500 degrees, because some of the current circuit boards in the production of Add a lot of different metal materials in it, and each metal material melting point are different, must reach a sufficient temperature to these metal materials layer by layer to separate out can. Once these three steps have been completed, the gold is almost ready to be separated and, once it has cooled, a golden "little gold" can be seen. This method of refining can not only produce gold, but also other precious metals such as silver, copper, lead, zinc, tin and other substances, but the main benefit is gold.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231