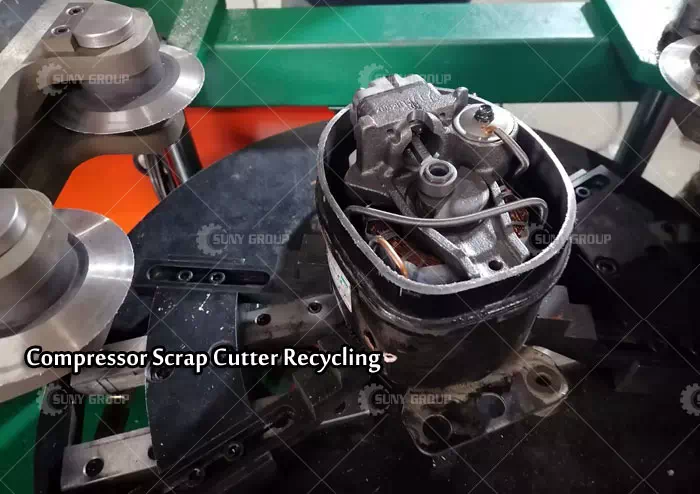

Compressor Scrap Cutter Recycling Machine

Compressor scrap cutters are used to cut compressors. When cutting compressors, a large amount of cutting dust is generated, and since compressors are basically made of ferrous material, the cutting dust contains a large amount of cutting and grinding dust and ferrous dust.

The existing cutting machines are not able to collect the dust and waste generated by the cutting work, so that the dust and waste generated by the cutting machines are not recycled in the air and affect the air environment; therefore, we propose a cutting machine for compressors with a waste recycling function.

SUNY GROUP has developed a compressor cutting machine with a waste recovery function to solve the problem that existing cutting machines do not collect the dust and waste generated by the cutting process, and thus the dust and waste generated by the cutting machine is not recovered in the air, which causes waste and affects the air environment.

The compressor cutting machine, including base, said base above the side of the fixed set of mounting bracket, said mounting bracket above the fixed set of shell cover, said shell cover is set inside the body of the cutting machine, and the body of the cutting machine and the mounting bracket fixed installation, said shell cover is opened on one side of the slot, said slot is set on one side of the dust suction hood, and the dust suction hood and the outer wall of one side of the shell cover by screw fixed connection said support bar is provided on one side of said mounting frame, and four support bars are provided, all four said support bars are fixedly connected to the base, said support bar is fixedly provided with a vacuum box above, said vacuum box is provided with a sorting mechanism below, said vacuum box is provided with a filtering mechanism inside, said support bar is provided with a fixed frame on one side, said fixed frame is fixedly provided with a mounting base on the upper surface, said mounting base is fixedly provided with a motor on the A motor is fixedly mounted on the top of said mount.

Said filter mechanism consists of a limit block, a filter frame, a dust filter plate, a rotating shaft and a vacuum fan, said limit block is provided with four, four said limit blocks are fixedly provided on both sides of the upper and lower inner walls of the vacuum box, said filter frame is inserted between the limit blocks, said upper and lower ends of the filter frame are fitted to the upper and lower inner walls of the vacuum box and slidingly connected, said dust filter plate is fixedly connected to one side of the inner wall of the filter frame said rotating shaft is inserted in one of the inner walls of the vacuum box and the rotating shaft is connected to one of the inner walls of the vacuum box by means of a rotating bearing, said ends of the rotating shaft extend to the outside and inside of the vacuum box respectively, said vacuum fan is fixedly connected to the end of the rotating shaft located inside the vacuum box.

Said filter frame is provided with ventilation holes on one side of the inner wall of the filter frame and one side of the dust box, and there are several ventilation holes, said rotating shaft is located on the external side of the dust box and the output end of the motor is fixedly connected through a coupling, said dust suction tube is fixedly provided on the other side of the inner wall of the dust box, and the two ends of the dust suction tube are extended to the external and internal sides of the dust box, said dust suction tube is located on the external side of the dust box and the dust suction The dust hood is fixedly connected to the dust hood and the dust pipe is fixedly connected to the dust hood at one end of the dust hood, and one end of the dust hood is fixedly connected to the dust hood, and one end of the dust hood is fixedly connected to the dust hood, and one end of the dust hood is fixedly connected to the dust hood.

The above is the introduction of the end-of-life compressor cutting and recycling equipment, the equipment is not only efficient and stable, but also has a smoke exhaust, dust removal function, in the cutting and recycling compressor at the same time, will not produce secondary pollution to the environment. If you are interested in this equipment, please contact us in time to give you detailed information and prices.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231