What are the advantages of broken bridge aluminum crushing and sorting machine equipment?

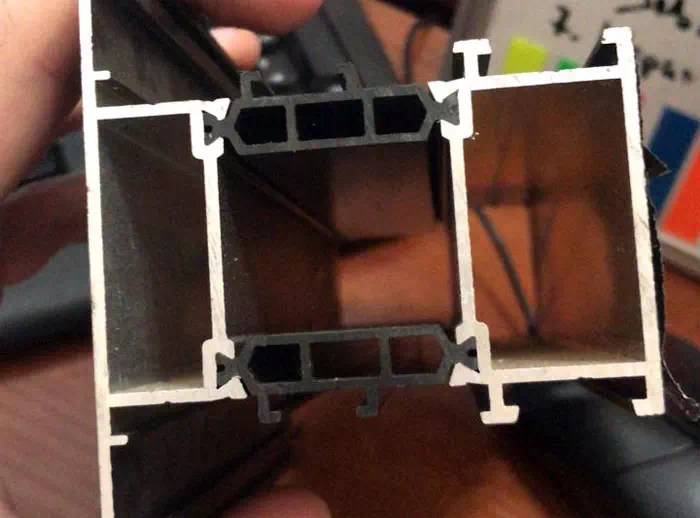

Broken bridge aluminum crushing and sorting equipment is also called broken bridge aluminum crushing and separation equipment in some places. It can effectively separate the aluminum and plastic of doors and windows, increase the separation rate of aluminum and plastic, and the recycled pure aluminum plays a role in recycling and reuse, saving energy. Increase economic benefits for customers under the premise of environmental protection.

Application scope of broken bridge aluminum crushing and sorting equipment:

Broken bridge aluminum crushing and sorting equipment is mainly used in broken bridge doors and windows, aluminum alloy materials, discarded household appliances, scrapped automobile copper and aluminum materials, plastic recycling and plastic product sorting, sorting and processing of broken bridge aluminum scraps, etc. The recycled broken bridge aluminum material has high purity and high recovery rate. In the comprehensive recovery, the processed material is equipped with reasonable sorting equipment, and the processing route is advanced and practical. After the broken bridge aluminum is crushed and sorted, the aluminum, plastics and other impurities can be completely separated to obtain pure aluminum, which improves the secondary utilization value of the processed materials. Therefore, broken bridge aluminum crushing and sorting equipment is widely used in sorting and processing.

The advantages of broken bridge aluminum crushing and sorting equipment are as follows:

1. Broken bridge aluminum crushing and sorting equipment has customized and non-customized specifications. The broken bridge aluminum crushing and sorting equipment is mainly designed for various broken bridge aluminum raw materials, and the miscellaneous aluminum containing metal plastics can be sorted and processed by the broken bridge aluminum sorting machine. Select frequency conversion control and high-speed pure copper motor configuration, environmental protection, low power consumption, stable and reliable quality assurance.

2. The main equipment of the broken bridge aluminum crushing and sorting machine includes bearing parts, magnetic roller parts, etc. The bearings are imported bearings, which have low noise and long service life and operate well. The magnetic roller adopts effective magnetic system protection, and uses the magnetic force application technology of the eddy current separator to prevent the magnetic system from falling off during high-speed operation. Separable metal particles are typically between 3mm and 100mm wide across.

3. The eddy current itself in the broken bridge aluminum crushing and sorting machine will generate a magnetic field opposite to the original magnetic field, and non-ferrous metals (such as copper, aluminum, etc.) will leap forward along their transportation direction due to the repulsive force of the magnetic field. To achieve separation from other non-conductor or non-metallic substances to achieve the purpose of sorting.

In addition to processing broken bridge aluminum, the aluminum-plastic sorting and recycling equipment developed and manufactured by SUNY GROUP also has a very good sorting and recycling effect on waste medical boards, aluminum-plastic boards and other aluminum-plastic wastes. If you are interested or need aluminum-plastic sorting and recycling equipment, please contact us in time.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231