Introduction of new energy vehicle lithium battery recycling and processing equipment

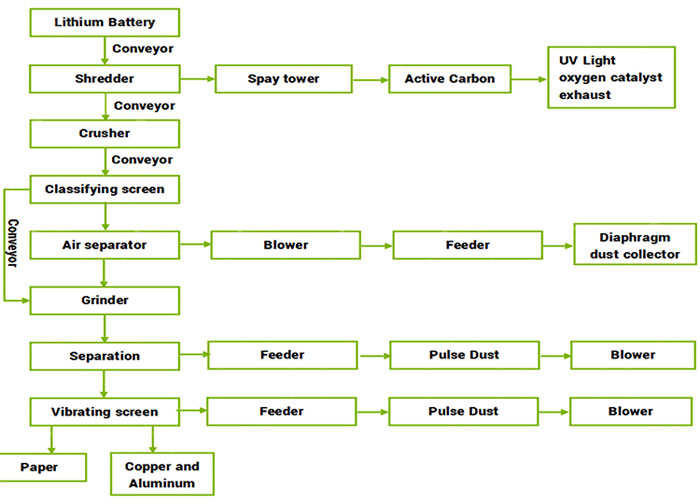

The new energy vehicle lithium battery recycling and processing equipment is mainly composed of two general direction systems: crushing and sorting. The waste and charged new energy vehicle lithium batteries are directly put into the charging station of the waste lithium battery recycling and processing equipment, and then the new energy vehicle batteries are recycled. The feeding conveyor of the processing equipment transfers the battery to the oxygen-depleted crushing equipment. The conveying equipment is fully sealed and has a negative pressure suction at the upper end to prevent the smell of damaged batteries from dissipating. All insulation systems are designed to prevent conductive discharge. The equipment is equipped with explosion-proof system, automatic input system of protective gas, automatic display system of oxygen content, automatic vacuum system, waste gas filtration system, and waste gas efflux system.

The crushed materials are volatilized into the sorting system by heat, and combined by magnetic separation, specific gravity sorting, negative pressure, and air separation. The recovery rate of magnetic iron is over 99.5%. More than 99% of the stainless steel shell of the copper block and aluminum block is recovered by sorting, and more than 98% of the positive and negative electrode sheets are sorted and recovered. After high-speed friction, the separation rate of copper and aluminum and positive and negative electrode powder reaches more than 98%.

The exhaust gas generated by vacuuming, comprehensive sorting and friction de-powdering is transported to the combustion system by separate pipelines, and the volatile electrolyte gas is transported separately through the insulation measures to isolate oxygen (the volatile gas of the electrolyte is kept warm to prevent the solidification of the electrolyte), and the pipelines are separated. Separate transportation avoids the danger of organic gas explosion, and the pyrolysis combustible gas insulation pipeline is transported and filtered separately into the combustion system to prevent condensation and deflagration of combustible gas.

New energy vehicle batteries contain copper and aluminum metals, positive and negative electrode materials, plastic separators, plastics and other materials that can be recycled and reused. The use of new energy vehicle lithium battery recycling and processing equipment can achieve good sorting significance. The utility model new energy vehicle battery recycling and processing equipment improves the utilization rate of battery positive and negative electrode materials of new energy vehicle power lithium batteries by 10%, the cobalt acid metal content in copper and aluminum metals is as low as 2%, and the sorting rate of plastic separators is higher than the industry The level is 20% higher. A complete set of new energy vehicle battery crushing equipment processing process equipment process line to achieve sustainable development of waste lithium-ion batteries, not only to alleviate the current state of lack of waste lithium battery raw materials, but also to separate and recycle waste new energy vehicle batteries The economic benefits of metal utilization in positive and negative electrode sheets are also promising.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231