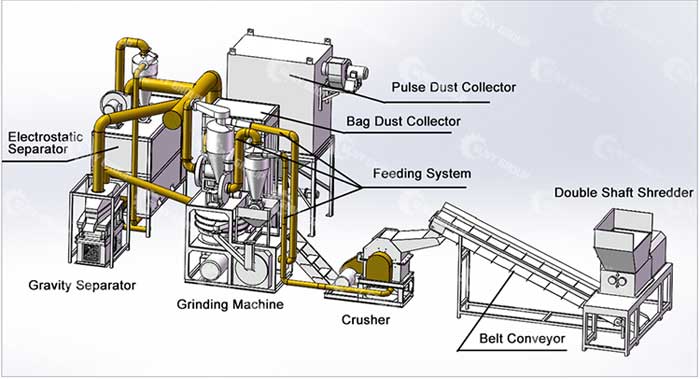

Small Household Crushing And Recycling System, Case Of Electronic Waste Shredder Production Line

The crushing treatment of electronic waste is a method of sorting by using the physical properties of the components, including disassembly, crushing, sorting and other steps. After sorting, the materials can be processed to obtain metal, plastic, glass and other recycled raw materials. This treatment method has the advantages of low cost, simple operation, not easy to cause secondary pollution, and easy to achieve large-scale.

The so-called electronic waste refers to electronic products that have been discarded or can no longer be used: discarded televisions, discarded old computers, old refrigerators, microwave ovens, discarded mobile phones, printed circuit boards, and used batteries. Waste electronic products can be divided into two categories: one is products with less harmful materials, such as refrigerators, washing machines, air conditioners, etc.; the other is products with materials that are more harmful to the environment, such as computers , TV picture tubes, used batteries, printed circuit boards, etc., automobiles, motorcycles, bicycles, etc.

Crushing and dismantling is the key to the recycling of electronic waste and scrapped vehicles. The degree of crushing is directly related to whether the metal and non-metal can be effectively dissociated, whether it can meet the particle size requirements of the sorting process and the sorting efficiency of metals and non-metals. , which directly affects the effect of recycling and is a key link in the entire recycling process.

Detailed introduction of the functions of electronic waste recycling equipment:

Crushing system: The crushing system takes the crusher as the main body.

The shearing crusher adopts the form of double-driven two-axis or four-axis, and the different types of crushing knives are arranged in a certain way to form a specific meshing method, so that different physical properties (elastic, brittle, rigid, hard, soft ) mixture can be decomposed and broken at the same time. (According to material characteristics, secondary or tertiary crushing can be used).

The main features of the crushing equipment are:

(1) The crushing output is large, and it only takes 6 seconds to crush an indoor cabinet air conditioner;

(2) The crushing force is large, and it can cut round steel with a diameter of 16mm and steel plate with a thickness of 5mm;

(3) With overload protection capability, the equipment will not be damaged when the equipment is overloaded;

(4) It has good separation ability, and can make polyurethane insulation material (foaming material) peel off from steel, plastic, and other objects well when broken (can reach more than 95%); it creates good conditions for automatic sorting (Great savings in sorting costs);

(5) The equipment has the function of controlling the particle size of some substances after crushing (using classification and crushing);

(6) The equipment is reliable in operation and stable in quality; the unique type structure makes maintenance and maintenance more convenient.

The automatic sorting system is mainly based on belt conveying equipment, wind sorting equipment, magnetic sorting equipment, and automatic packaging equipment.

The scope of application of this process:

Suitable for recycling of household electronic waste; car dismantling and recycling plant;

The electronic waste intelligent shredding system achieves automatic dismantling and separation of electronic waste through intelligent processes such as crushing, separation, sorting, and dust removal. It not only achieves effective shredding, but also greatly improves the efficiency of subsequent resource reuse. The acclaimed e-waste shredding solution.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231